Carbon Floating Shaft Composite Coupling

The Carbon Floating Shaft Composite Coupling also called composite coupling. Carbon Floating Shaft Composite Coupling transterring the power installed between the motor and reducer of the cooling tower fan is as follows:

1. weighs up to 80% lighter than general steel coupling because of composite material

2. Therefore this makes it easier to install and does not require a separate bearing device even though it is a long shaft

3. Rotational are guaranteed balancing tests according to ISO1940-1, 6.3 grade

- Information

- Video

- Download

Introduction of Carbon Floating Shaft Composite Coupling:

Owing to the low weight of the carbon-composite material, the weight of composite coupling is about 20% of the coupling made by the steel material. Once the composite material is used, the length of the axis of composite coupling can be enlarged by 80% more than the coupling made by the steel material without using the fixture and bearings while transmitting power at high speed.

As the surface is coated to prevent the moisture absorption of composite materials, the high fatigue life is guaranteed even though they are exposed to the corrosion environment.

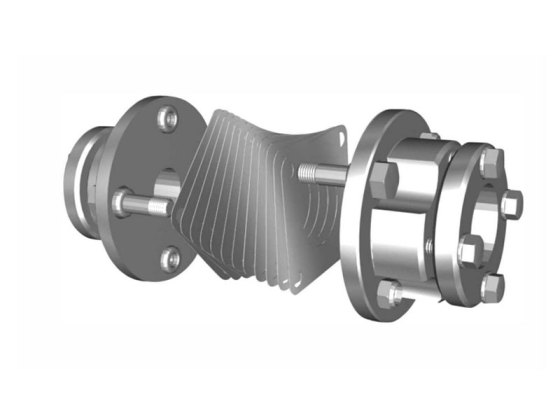

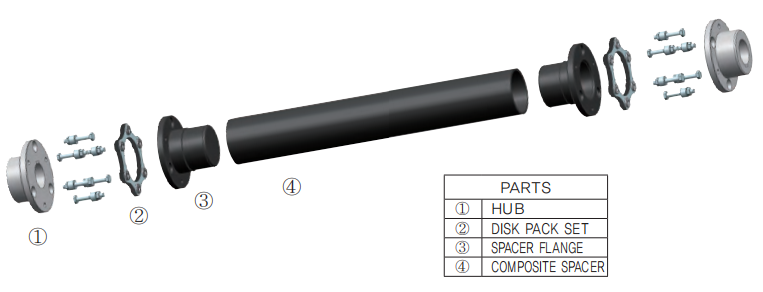

Both ends of the composite coupling are in the form of flexible element, The flexible element is a unitized disc constructed of advanced composite material and stainless steel bushings. The elements are encapsulated in urethane for ease of handling, and to prevent fretting and corrosion.

Rotation quality is guaranteed through 100% balancing test in accordance with ISO1940- 1 G 6. 3 grade.

Coupling flanges are available in three materials: carbon fiber, fiberglass amalgamation or alloy steel.

Characteristics of KUDOSWORLD Carbon Floating Shaft Composite Coupling

Corrosion resistance

High-misalignment capacity

Excellent fatigue resistance

Low weight

Easy installation and disassembly

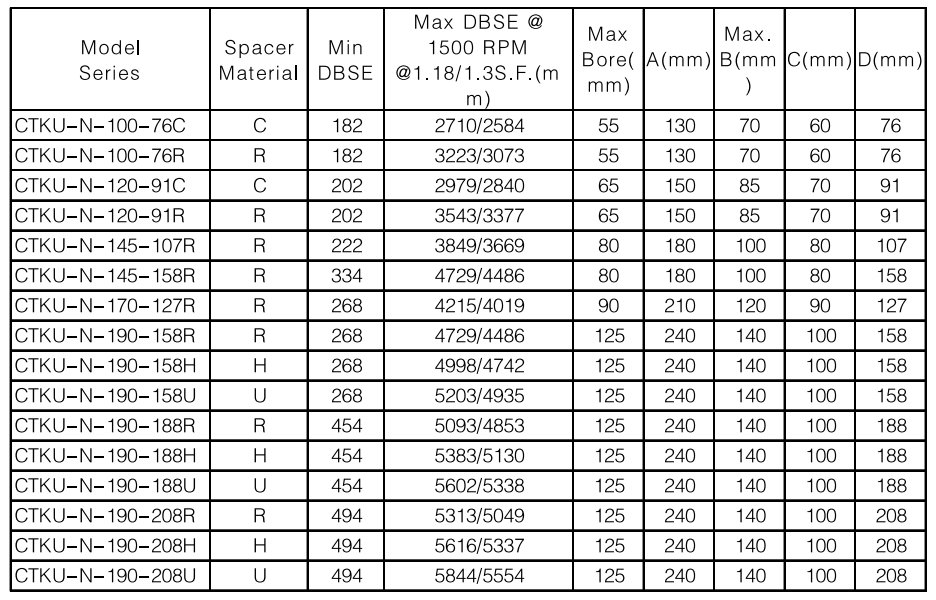

C: Fiberglass Amalgamation

R: Standard Carbon Fiber

X: Medium To High Modulus Carbon Fiber

U: High Modulus Carbon Fiber

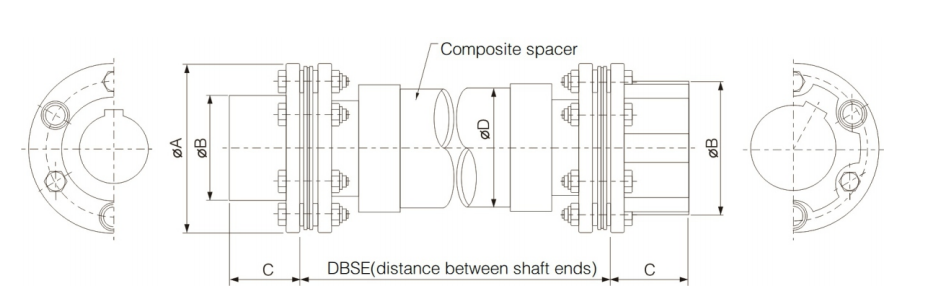

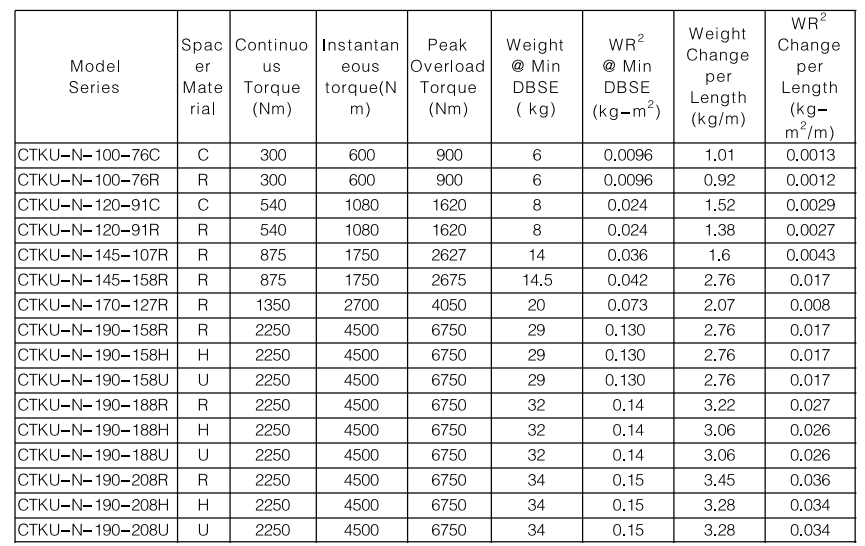

The standard weight and WR2 values are at minimum DBSE and standard minimum bore for a complete assembly. To determine the total weight or inertia, subtract the minimum DBSE from the total DBSE required and multiply that value times the WT and/ or WR2 change per length, then add that calculated WT or WR2 to the minimum DBSE values. Values may vary slightly depending on the actual bore and key size.

Company Style

Kudosworld is an industrial technology group with businesses all over the world. We provide a series of solutions, including advanced technology, manufacturing, products and precision services. Provide products and services for key markets such as new energy, oil and gas, mines, ports, steel, etc. We take Kudosworld (China) as the core of operation and management, rely on the technology of Kudosworld in Germany, and cooperate with global production bases for processing and manufacturing.