Torque Limiting Safety Coupling

KUDOSWORLD Torque Limiting SaFety Coupling moves through rollers or balls to achieve full disengagement when the torque is calibrated. It is suitable to work under the condition of high torque with high stability and compact structure.

KUDOSWORLD Torque Limiting SaFety Coupling Main applications: packaging machinery, labeling machinery, bottling machinery conveyor, rolling mill, scraper, straightener, ship loader, etc

- Information

- Download

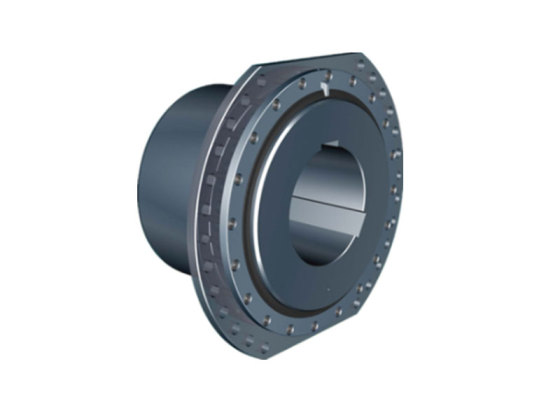

KUDOSWORLD Torque Limiting Safety Coupling, RB Type--Precision Ball and Roller Type

KUDOSWORLD Torque Limiting Safety Coupling RB type realizes movement transmission through bals or rollers, which can provide overload protection and has the following characteristics:

Various types of structure, suitable for different occasions

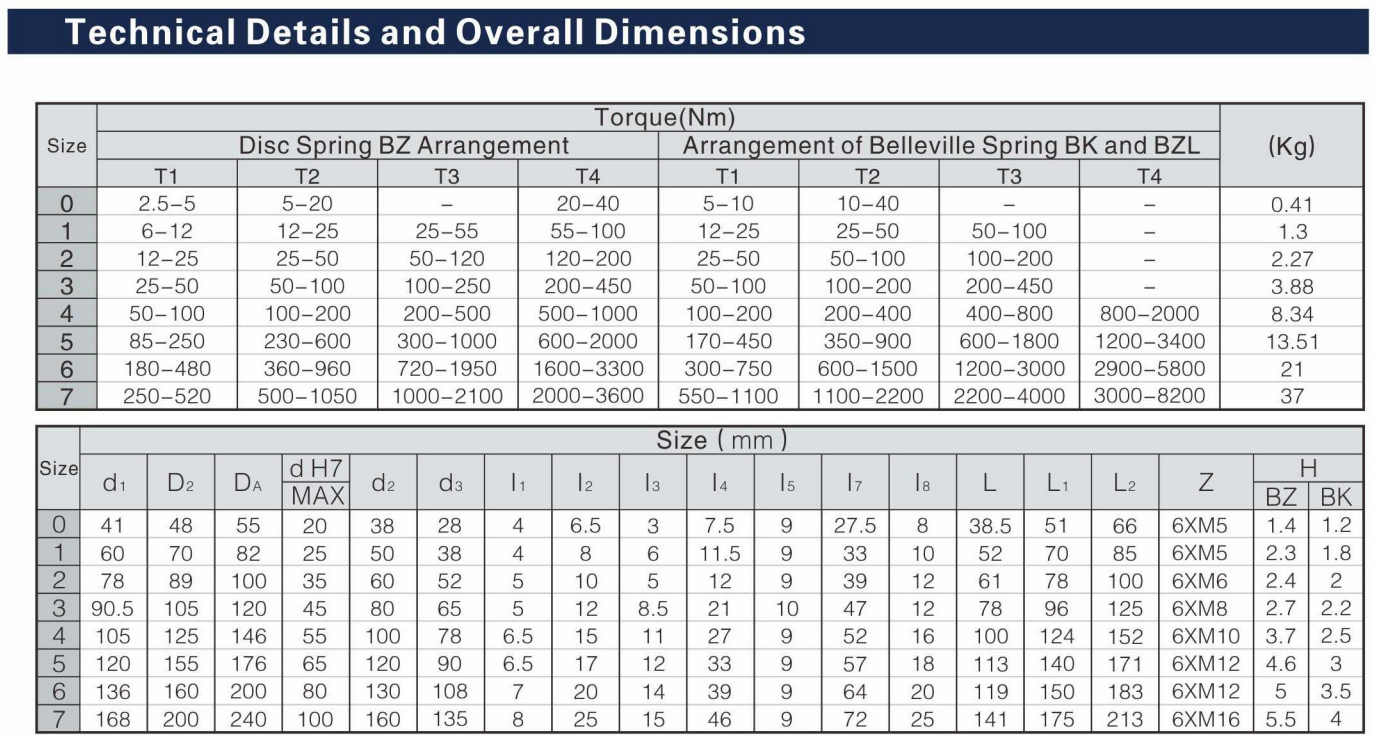

The slip moment can reach 8200Nm

It can provide step-by-step, synchronous and failure protection

Easy installation and adjustment of torque

The peak value of torque can be reduced

High repeatability

Suitable for wet and oily environment

High performance materials are used to prolong the service life

The power source can be cut off in case of overload

Automatic clutch

There is no backlash between the shaft and the shaft sleeve

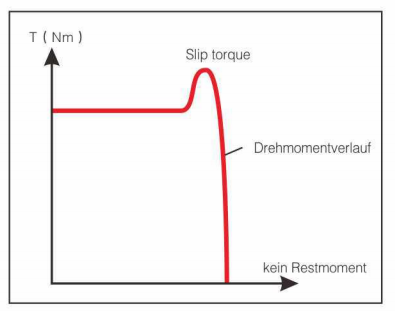

Zero Residual Moment After Overload and Slipping

1) The maximum slip moment can reach 8200nm.

2) Allowable maximum speed is 5000rpm

3) Driving end and driven end can be kept completely disconnected

4) When the overload reaches the set slip, the slip will occur immediately.

5) In case of slipping, limit switch or electronic sensor can be used to send out signal

6) The re engagement after slipping can be operated manually or mechanically.

7) The type with elastic coupling can be used for shaft to shaft connection

8) Easy installation and debugging

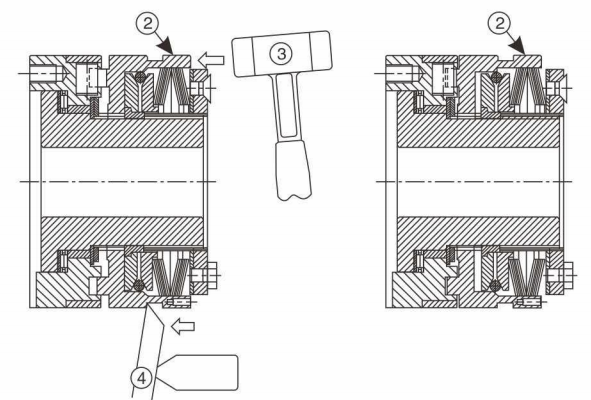

Fail Safe Reengage Instructions

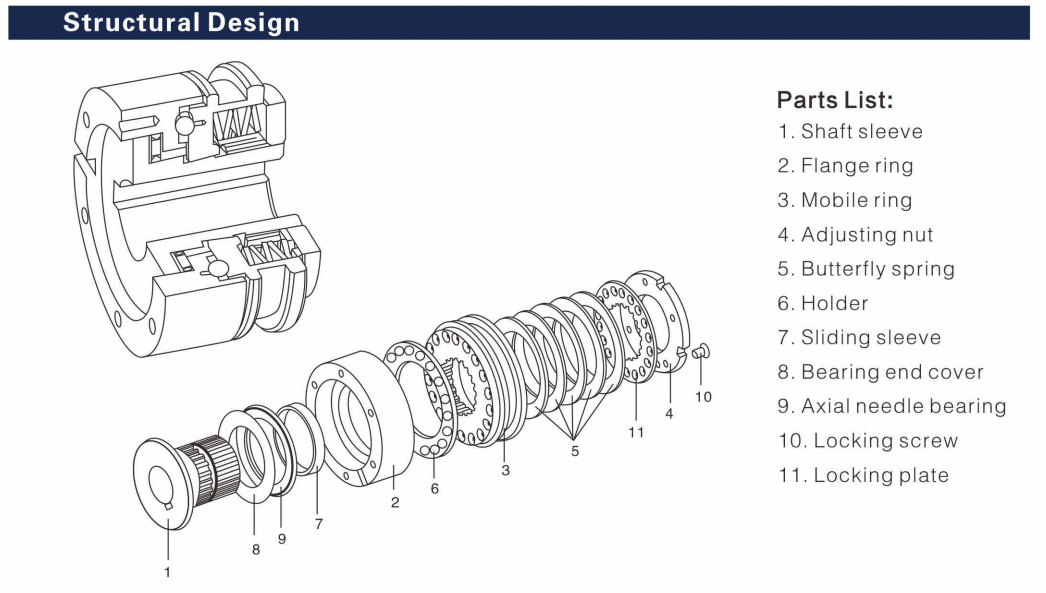

After the moment limiter slips, it only needs to apply an axial force on the moving ring(2) to engage again. The operation can be completed with various tools

- Use rubber hammer(3) to directly knock the moving ring axially(see Figure)

Using a lever(4)

- Use pneumatic or hydraulic engagement device (automatic engagement)

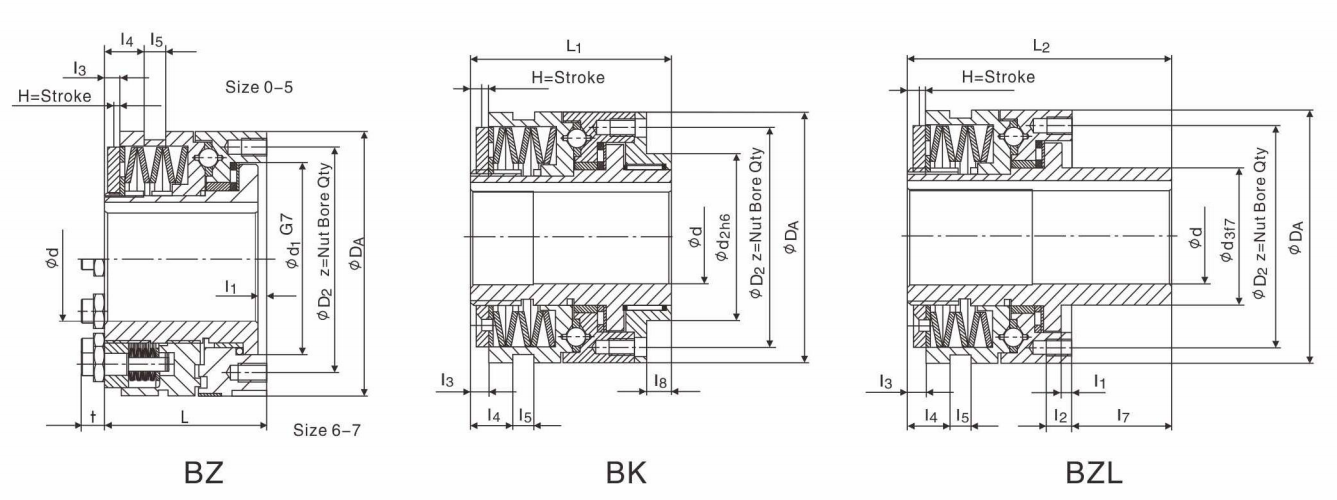

KUDOSWORLD Torque Limiting Safety Coupling——RB type standard structure

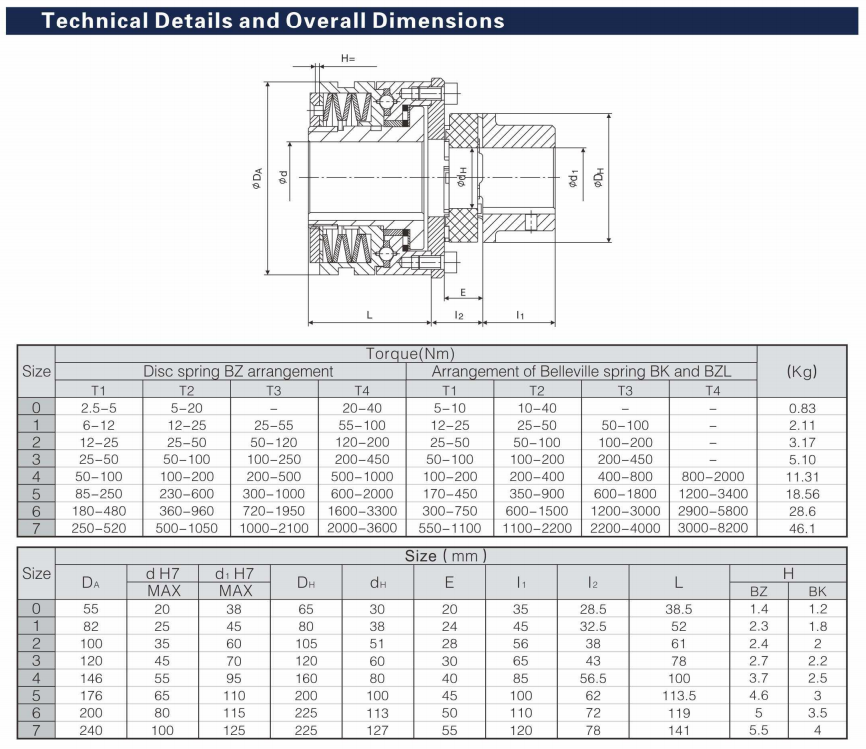

Standard RB torque limiter torque range 2.5-8200Nm, maximum opening φ100mm.

Standard single point reset, according to requirement 15° 30° And 60° etc.

It can be equipped with spiral spring, with high sensitivity of torque setting.

There are three reset modes: step, synchronous and fail safe

It can be installed on the equipment for torque setting, with high stability.

The tolerance of finished hole diameter is H7 accordirg to ISO standard, and the tolerance of keyway width is JS9 according to DIN6885/1.

The surface is treated with anti-corrosion.

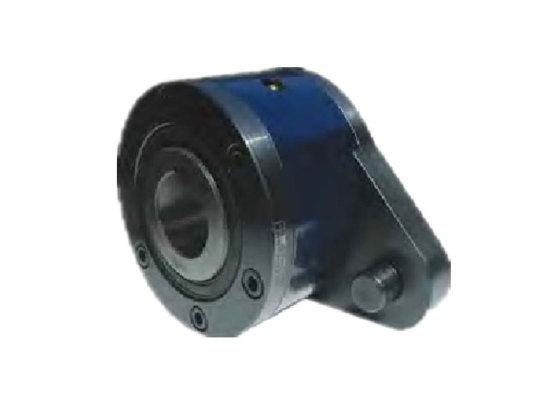

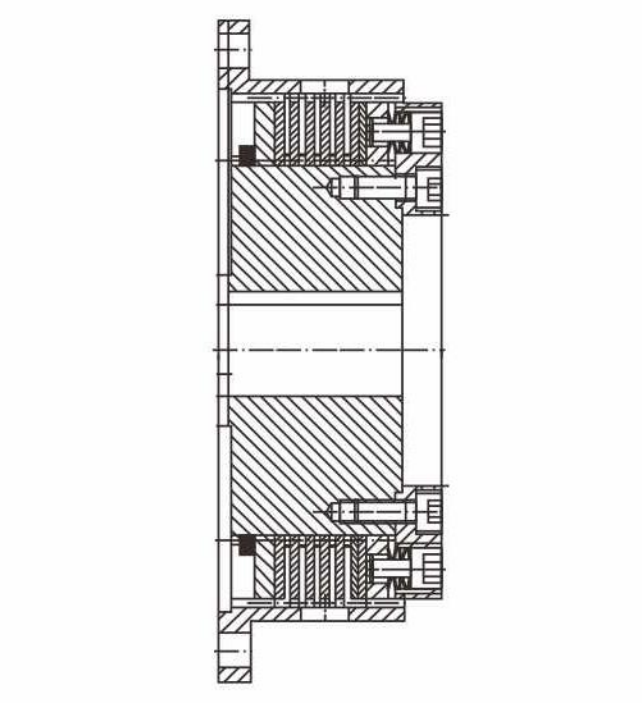

KUDOSWORLD Torque Limiting Safety Coupling——RB-G type standard structure

RB-G moment limiter with shaft to shaft connection

Axial insertion, easy to install

Can compensate installation deviation

There are three reset modes, step-by-step, synchronous and fail safe

Can be installed on the equipment for torque setting

A variety of elastomers to choose from

The tolerance of finished hole diameter is H7 according to ISO standard and The tolerance of keyway width is Js9 according to DIN6885/ 1 standard

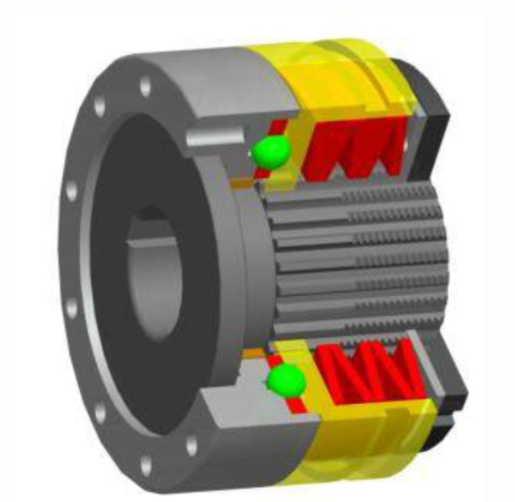

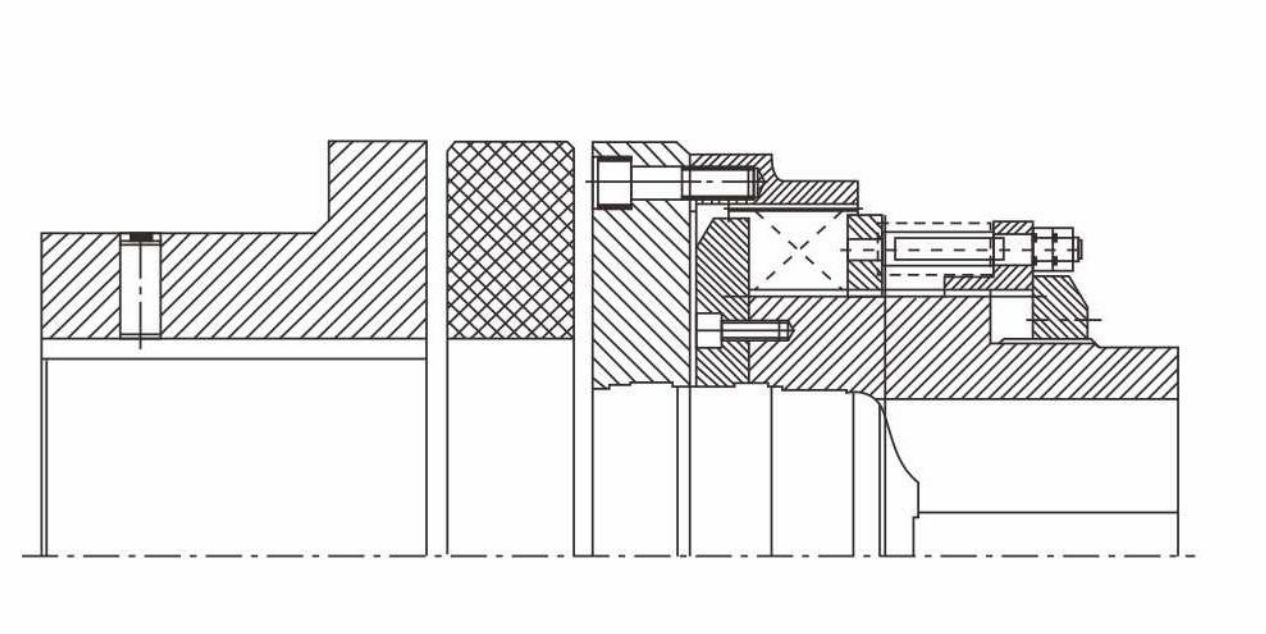

KUDOSWORLD Torque Limiting Safety Coupling——RD Multi Disc Friction Type

Friction plate material iron-based powder metallurgy

High wear resistance

Large torque adjustment range

Surface anti-corrosion treatment

It can be equipped with various types of couplings to facilitate shaft to shaft connection

Suitable for heavy industry applications such as fan, coal machine industry, large assembly line, etc

Standard type

The body can be lengthened according to the actual requirements.

Special anti-corrosion and anti rust treatment can be carried out as required.

It can be connected with keyway, expansion sleeve or other locking device as required.

Friction plate can be replaced separately.

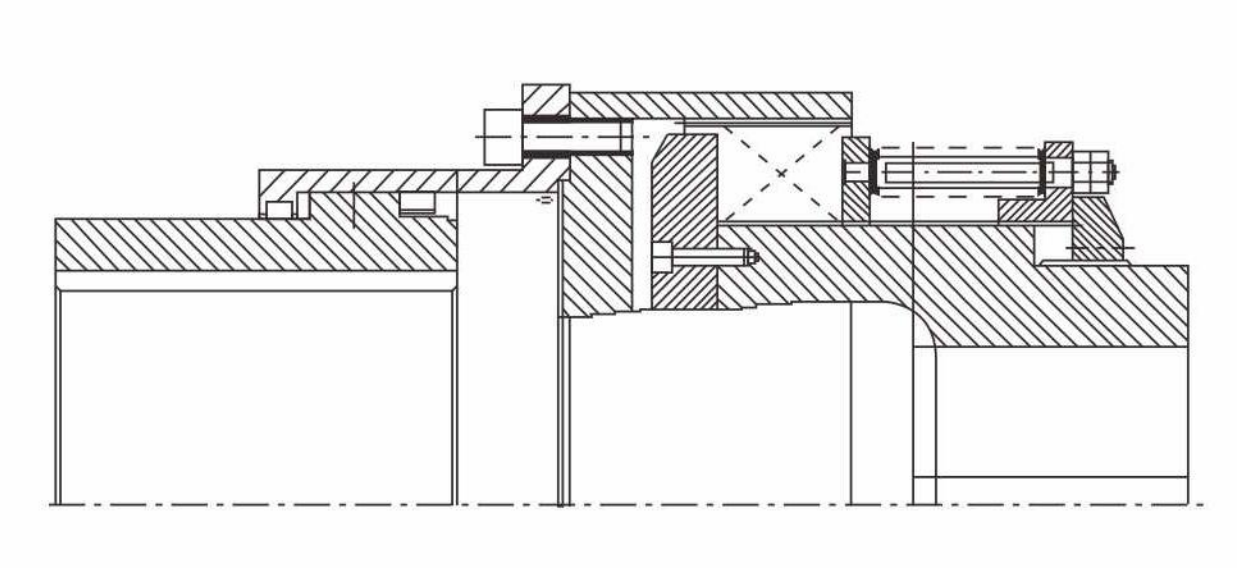

2. Torque Limiting with elastic coupling

The body can be lengthened according to working conditions.

It can be lengthened according to actual requirements.

It can be connected with keyway, expansion sleeve or other locking device as required.

Friction plate can be replaced separately.

3. Torque Limiting with with gear coupling

Various rigid coupling bodies can be equipped according to working conditions It can be lengthened according to actual requirements.

It can be connected with keyway, expansion sleeve or other locking device as required.

Friction plate can be replaced separately.

Over the past decades, we have made contributions to the development and implementation of hundreds of projects where product quality, technological progressiveness and reliability are the prerequisites for success. From finding the best customer solution to complex project delivery, customer trust proves our experience, reliability and professionalism.