- Home

- >

News

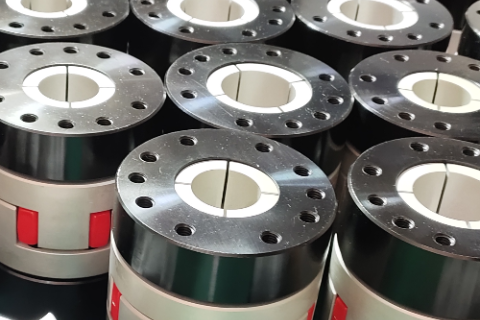

In June, conveyor company SIA Akonit came to our company to investigate Fluid coupling products and gear coupling products

The use and maintenance of variable speed hydraulic couplings should be carried out from three aspects: pre start inspection, running, repair and maintenance.

When using and maintaining the Fluid coupling, attention should be paid to the installation, disassembly, liquid filling, regular inspection and the provision of protective devices

As we all know, no matter what type of universal joint, after a long time of operation, it is inevitable that there will be a series of major or minor problems. If left unchecked, it will inevitably cause trouble and affect production over time. Therefore, in order to ensure the normal operation of the universal joint coupling and effectively extend its service life, we need to carry out necessary maintenance work on the universal joint.

During the use of elastic couplings, it is necessary to select appropriate flexible couplings based on actual performance requirements to ensure their correct use.