Disk Couplings Are Subject to Peak Torque Limitations

2023-09-08 15:00For high-speed transmission shafts, balanced couplings, such as elastic couplings, etc., should be used instead of eccentric slider couplings. The magnitude and nature of the torque to be transmitted and the requirements for vibration damping functions should be considered.

The two hubs of the disc coupling are generally forged from stainless steel or 45# steel forgings, and the discs pack in the middle is usually cut from stainless steel. The low temperature resistant type made of stainless steel is better. If the disc coupling works with center misalignment for a long time, and the center deviation generated during operation exceeds the compensation range of the disc coupling, the disc coupling will be limited by the peak torque.

There is also the fatigue strength problem of the disc coupling itself, that is, the heat treatment problem of the disc coupling. The disc coupling should follow the corresponding heat treatment process while ensuring the correct selection of materials.

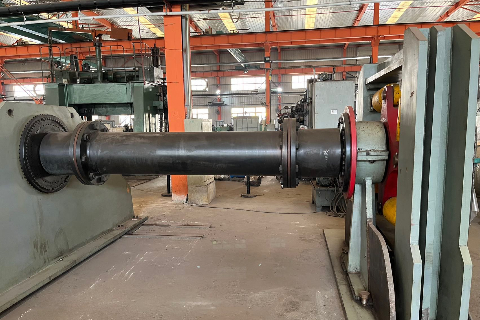

Disc coupling transmission usually consists of one or several disc couplings connecting the main and driven shafts to form a shaft train transmission system to transmit rotation or motion.