Reverse Rotation Characteristics Of claw Elastic Coupling

2023-12-12 15:00The claw elastic coupling has good balancing function and is suitable for high-speed operation conditions, but the transmission torque is limited. Once the elastomer is damaged or fails, torque transmission does not stop. The claws of the two hubs engage together to continue transmitting torque, which is likely to cause problems in the system. The elastomers of various elastic materials have different hardnesses and temperature-withstanding capabilities. Appropriate materials should be selected to meet the functional standards for practical use. Clockwise and counterclockwise reversal characteristics of claw-type elastic couplings are the same.

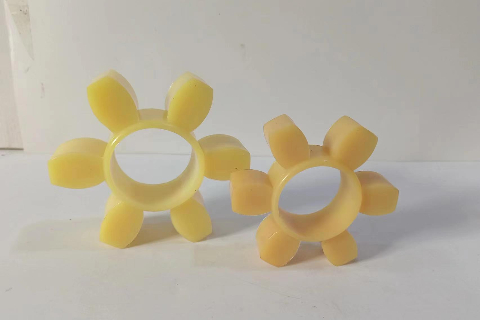

The claw elastic coupling uses elastic elements placed between the two hubs to connect. The structural standards of the two hubs are the same. There are multiple lugs on each end surface, which are placed between the convex parts of the elastic element in sequence, and the contact torque is transmitted from the driving shaft to the driven shaft. The load distribution on the contact surface of the torque-transmitting claw is related to the shape of the contact part. As the coupling diameter increases, the unevenness of the load distribution increases. This uneven load distribution will be further increased if there is a gap between the working surface of the elastic element and the hubs. The load distribution on the working surface of the paw is uneven, and the load between each loaded paw also tends to be uneven. The characteristics of the claw coupling are few parts, a standard shape, and a wide range of elastic element hardness classifications.