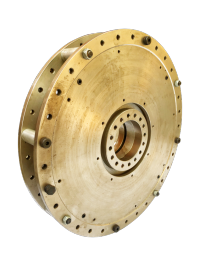

Basic Permanent Magnetic Coupling

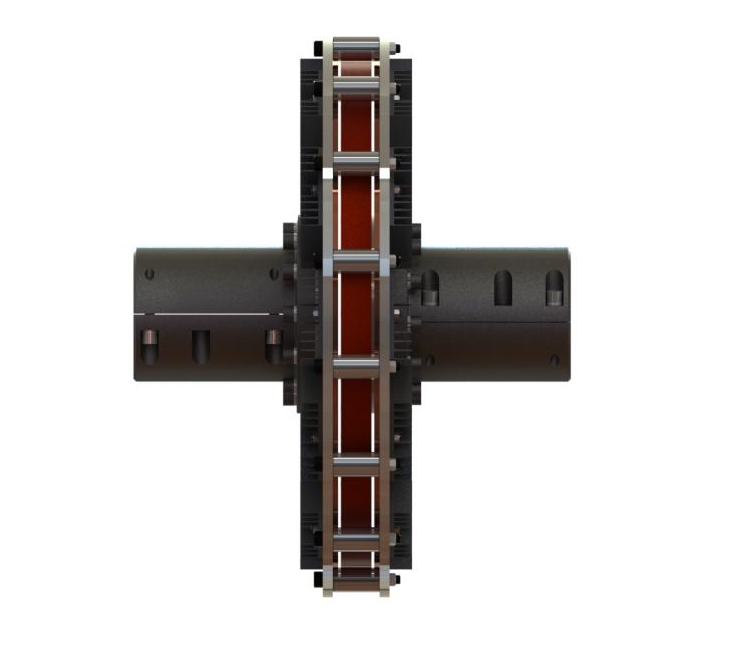

1.Dual permanent magnet discs provide smoother and more reliable operation for standard permanent magnet couplings.

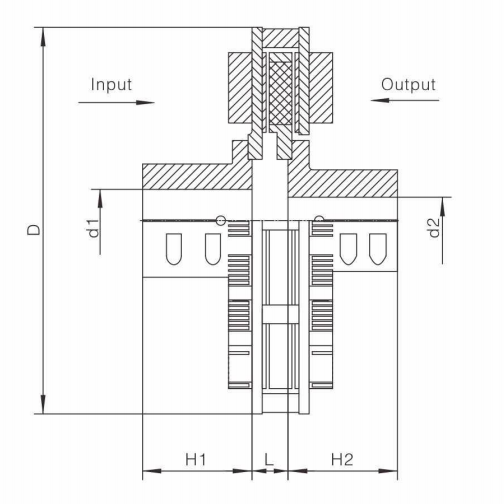

2.ENERGY saving from 5% to 50% by changing gap. Specially designed for pump and fan transmission.

- KUDOSWORLD

- CHINA

- 6-8 WORKING WEEKS

- 1,000 SETS/YEAR

- Information

- Video

- Download

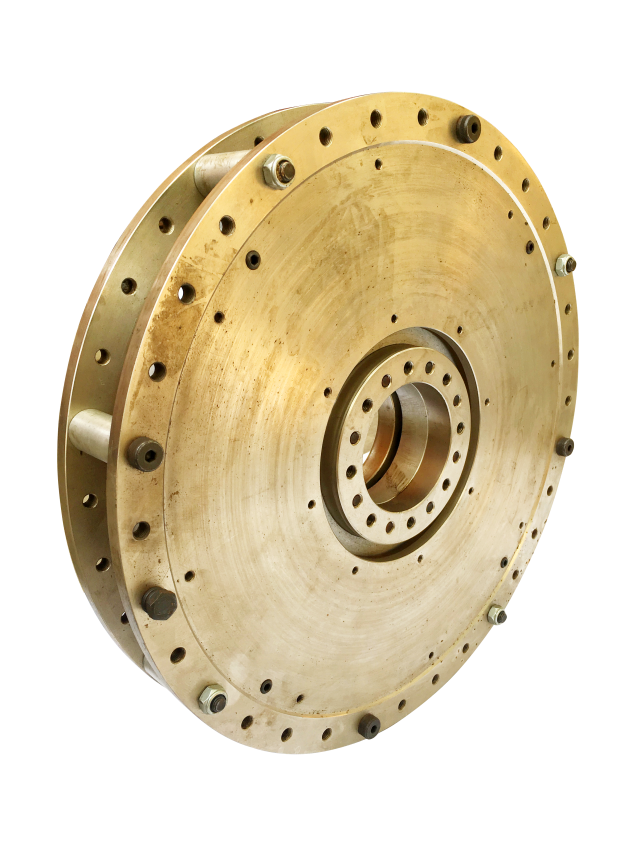

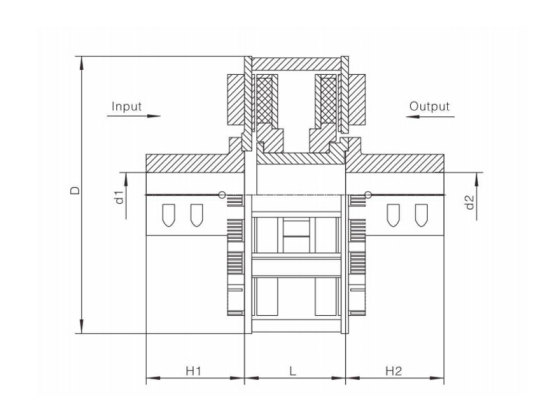

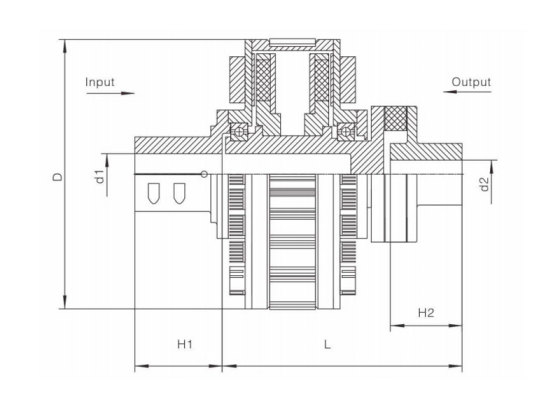

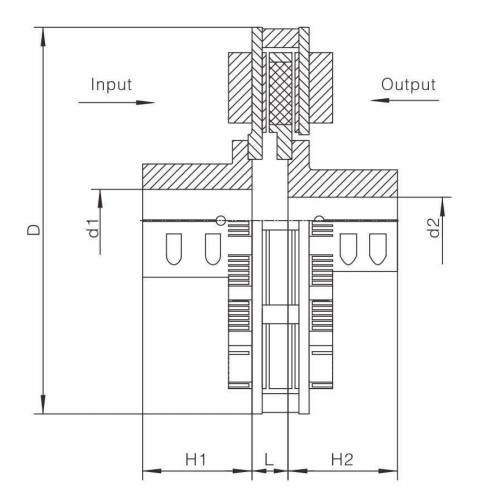

Basic permanent magnet couplings generally consist of two parts: a permanent magnet plate and a conductor rotor. The structural form of our company's standard permanent magnet coupling has been adjusted. The plate of the basic permanent magnetic coupling is adjusted from a single plate to a double ones. After design optimization, the basic type of permanent magnet coupling operates more smoothly, safely and reliably. Compared with the previous design, the new design makes the basic form of permanent magnet coupling more compact and applicable to a wider transmission range.

Features:

Basic permanent magnet couplings Can realize soft start of motor;

standard permanent magnet coupling with flexible connection effectively eliminates system vibration;

The basic permanent magnetic coupling with higher eccentric tolerance of axial deviation on alignment;

The basic type of permanent magnet coupling’ structure is simple, no need to change the foundation, and it is convenient to transform the original system;

Maintenance-free and long service life for the basic form of permanent magnet coupling;

The basic form of permanent magnet coupling is suitable for power, steel, mining, coal, chemical, lifting, paper making, textile, shipbuilding, cement and other industries with power less than 800KW prime mover.

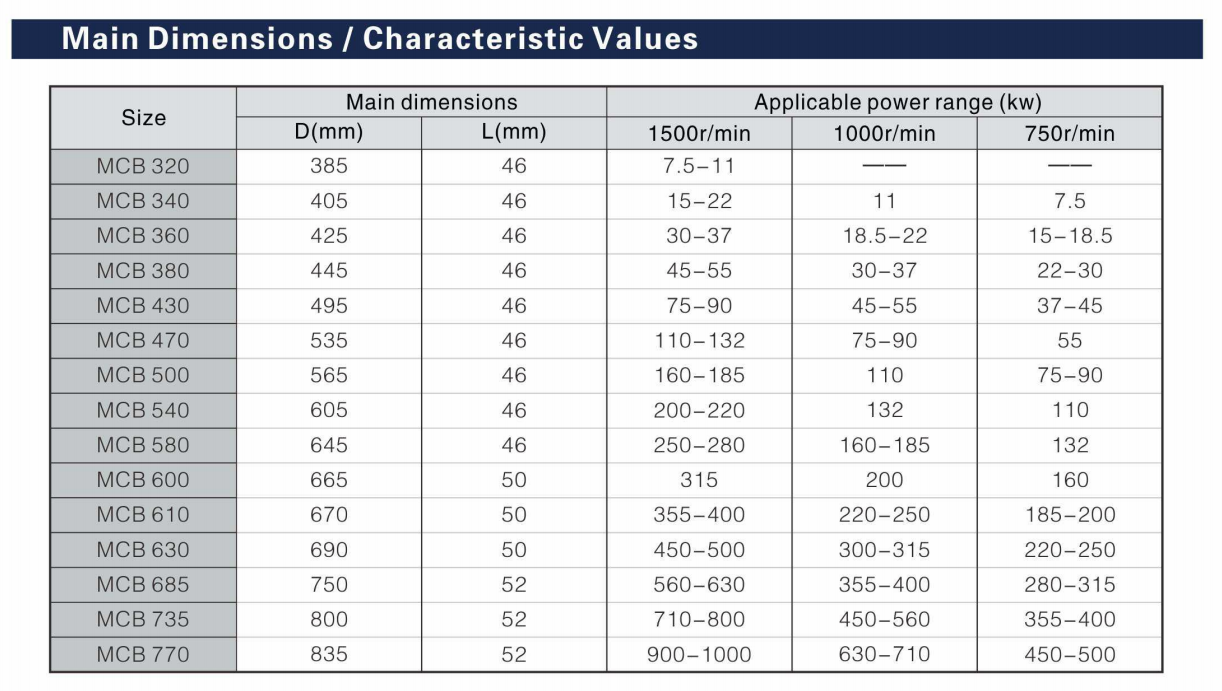

MCB standard permanent magnet coupling

Applications

The standard permanent magnet coupling is suitable for difficult centering equipment.

The standard permanent magnet coupling is suitable for power, steel, mining, coal, chemical, lifting, papermaking, textile, shipbuilding, cement and other industries with power less than 800KW prime mover.

In order to fulfill our commitment, we will:

★ Offer pre-sale and post-sale services.

We have a professional technical team that provides services such as product model selection, technical consultation, special working condition program design and on-site surveying and mapping.

★ After delivery, the after-sales team will provide technical services such as equipment installation, commissioning, daily maintenance guidelines.

★ We will pay regular visits to customers and maintain close communication with customers to gain feedback, as to address newly-arisen issues and provide timely remedy.

★ 24-hour service to ensure timely contact, and quick response.