Fully Closed Torque Limiting Permanent Magnetic Coupling

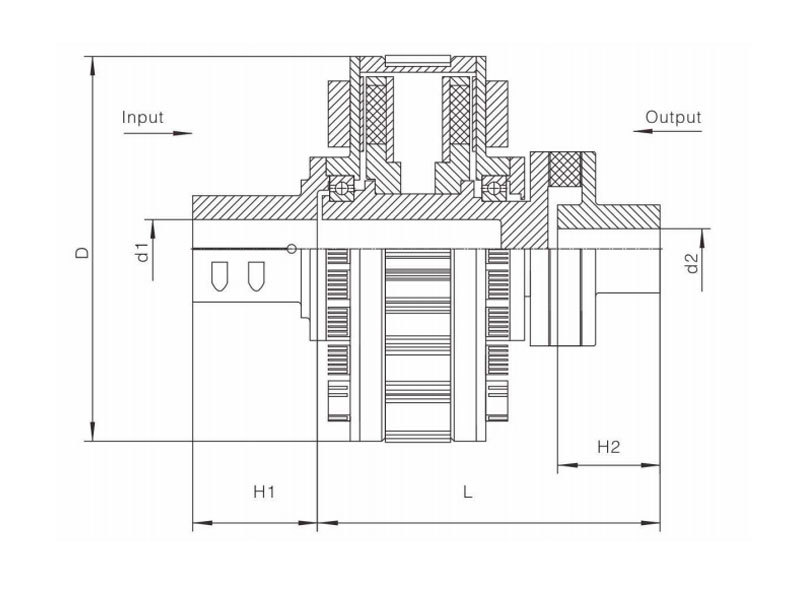

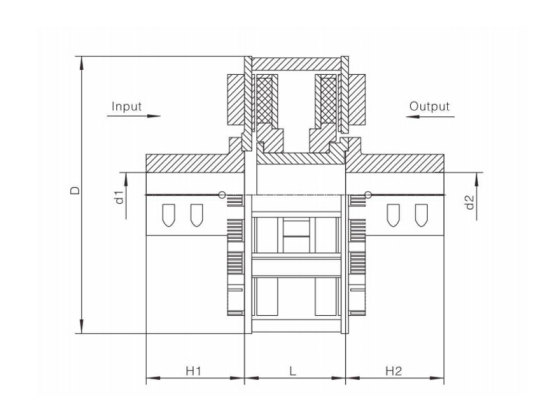

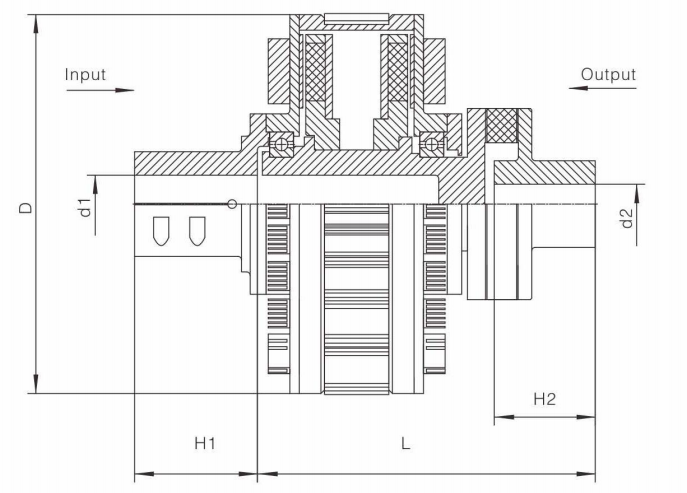

1. The limited moment totally enclosed permanent magnet coupling is composed of permanent magnet rotor, conductor rotor and closed chamber.

2. The permanent magnet rotor and conductor rotor of this kind of permanent magnet coupling are completely enclosed in a space to prevent impurities from contacting with them and extend the service life of the permanent magnet coupling.

3. LMC-TC Fully Closed Moment Limiting Permanent Magnet Coupling 's principle and pertormance are basically the same as that of LMC.

- KUDOSWORLD

- Information

- Video

- Download

About Fully Closed Torque Limiting Permanent Magnetic Coupling:

The Permanent Magnet Coupling is a device which transmits the torque from the motor to the load through the air gap between the conductor and the permanent magnet. It can realize the transmission mode without mechanical connection between motor and load.

Classification:

Due to the different air gap adjustment methods, permanent magnetic devices are divided into 3 different types such as standard type, delayed type, torque-limited type, and speed-regulated type.

The standard type: The air gap length is not adjustable

The delayed type and the torque-limited type: The length of air gap can be adjusted to meet the requirements of different occasions.

The speed-regulated type: The adjustment range of air gap length is the largest. The speed can be adjusted by adjusting the air gap length. Equipped with air gap adjustment mechanism.

Similarities of the 3 types are that The magnetic circuit structure is basically the same, based on the standard type.

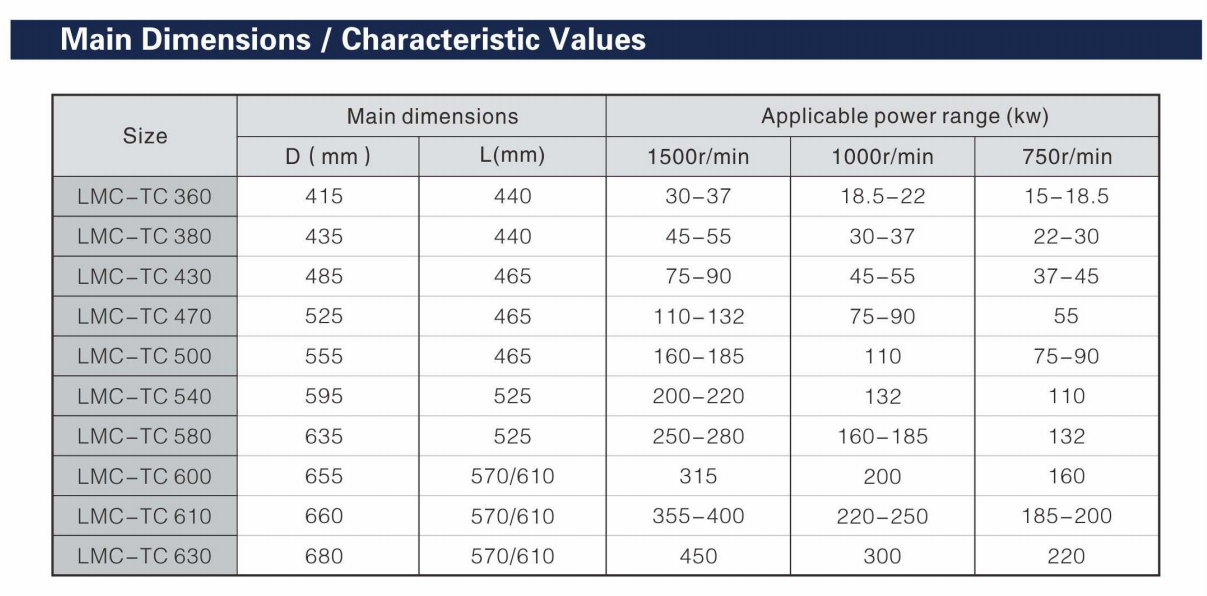

LMC-TC Fully Closed Moment Limiting Permanent Magnet Coupling

Applications

Fully Closed Moment Limiting Permanent Magnet Coupling is suitable for all kinds of bad working conditions, which need soft start, unstable load and overload protection. For example: elevator, crusher, belt conveyor, bucket wheel, etc

How Fully Closed Torque Limiting Permanent Magnetic Coupling works:

Fully Closed Torque Limiting Permanent Magnetic Coupling realizes the transmission of torque from the motor to the load through the air gap between the copper conductor and the permanent magnet. This technology achieves the mechanical coupling of the driving side (motor) and the driven side (load). It works by a permanent metal oxide magnet at one end interacting with an induced magnetic field at the other end to generate torque. 2 separate components with no physical contact.

The magnetic rotor assembly contains a large number of permanent magnets mounted on the load shaft. There is a gap (called an air gap) between the two separate elements. In this way, the original hard (mechanical) link between the motor and the load becomes a soft (magnetic) link. By adjusting the air gap between the permanent magnet and the conductor, the starting characteristics can be changed, and the output torque and rotational speed on the load shaft can be changed

Our certificate: