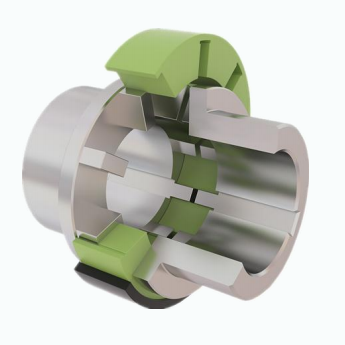

Flexible Flex Coupling

1. Designed to allow for quick and easy element replacement;

2. Removal of hubs or the realignment of motors or drives is not required;

3. Advanced production methods and allow for a higher capacity;

4. Non-lubricated and flexible urethane;

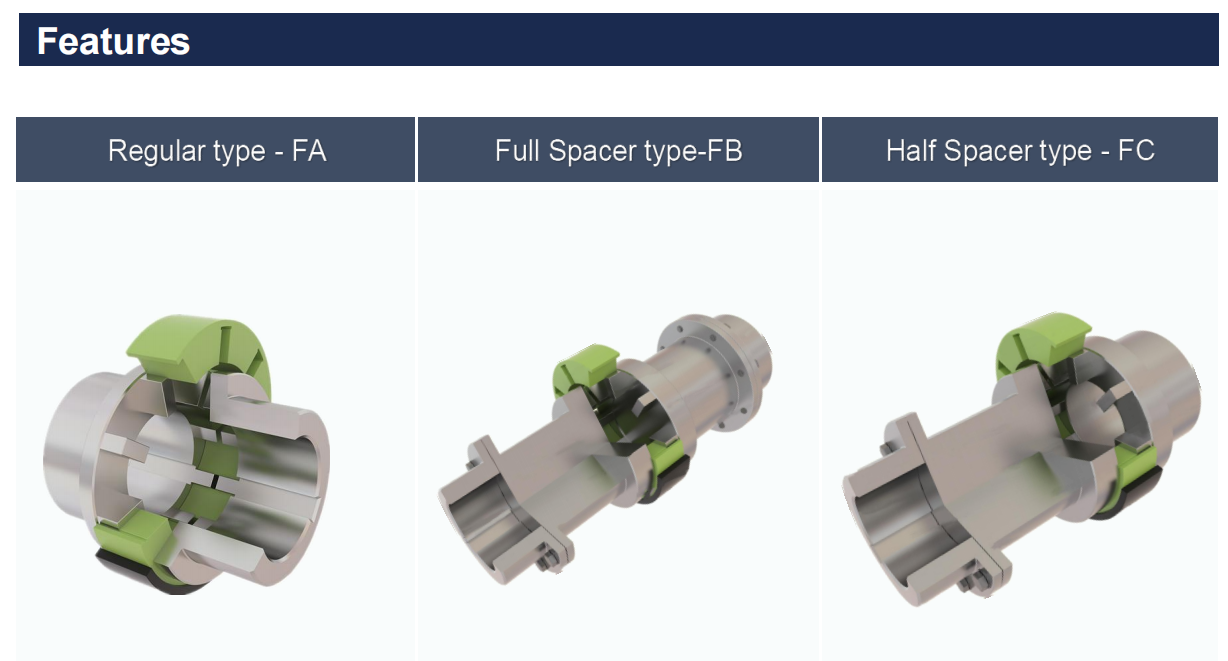

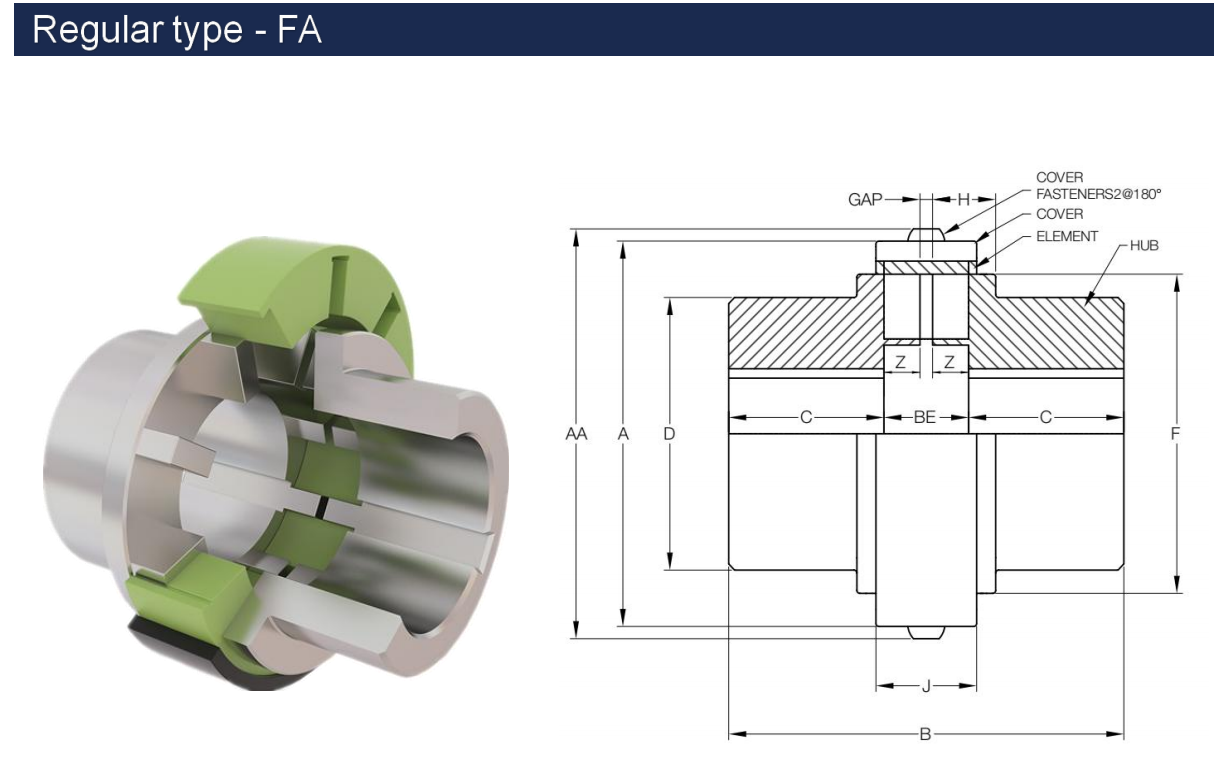

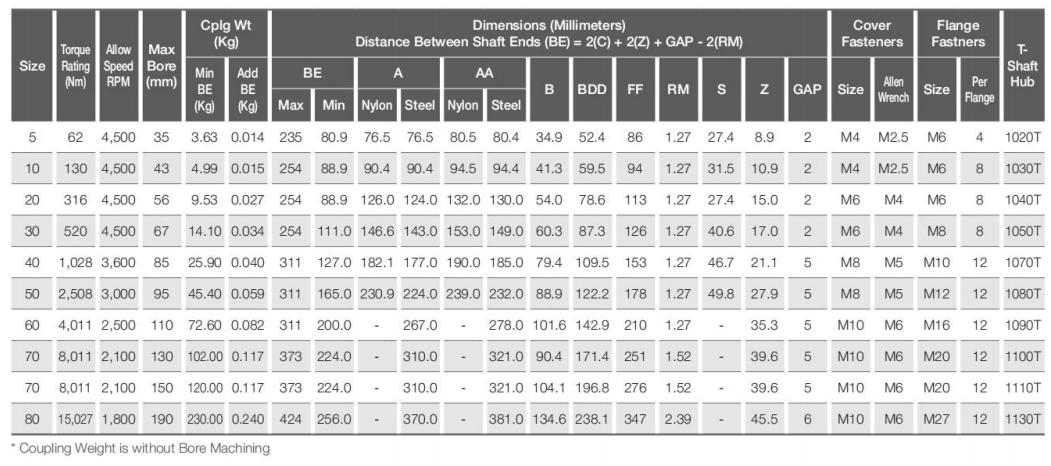

5. Available in both close-coupled and spacer designs;

6. Flexible Flex Coupling is Great resistance to wear and chemicals.

- Information

- Download

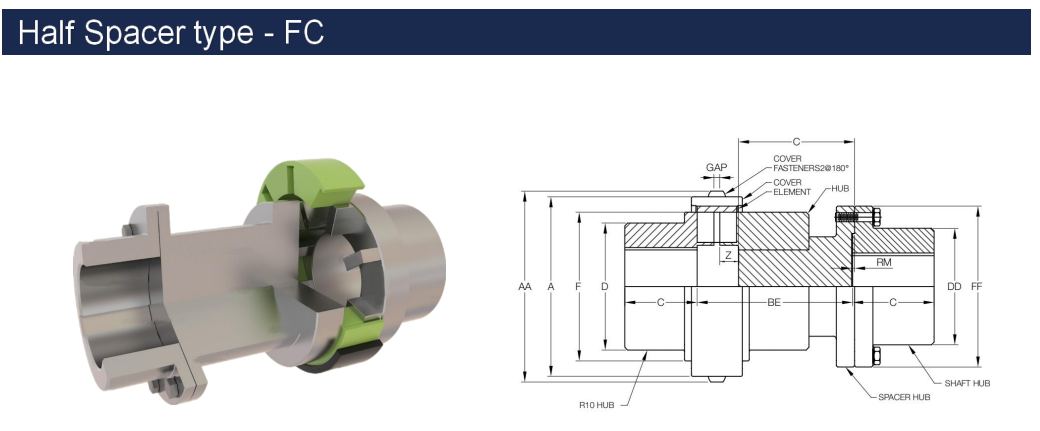

Introduction to Flexible Flex Coupling:

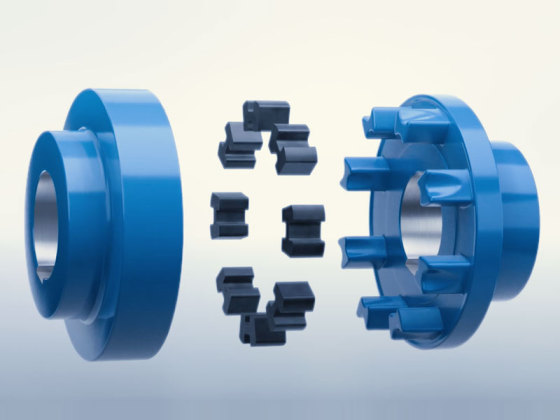

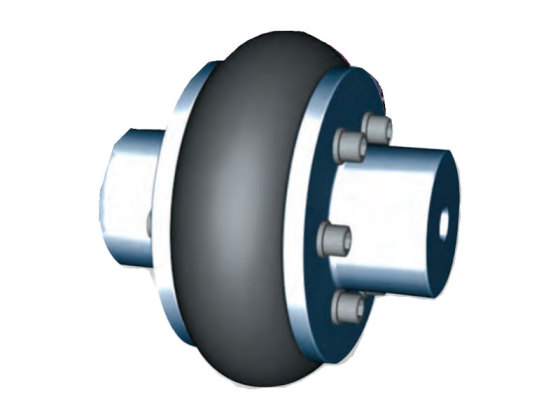

Kudosworld Flex Coupling is designed to allow for quick and easy element replacement. Removal of hubs or the realignment of motors or drives is not required, which in turn reduces overall downtime.

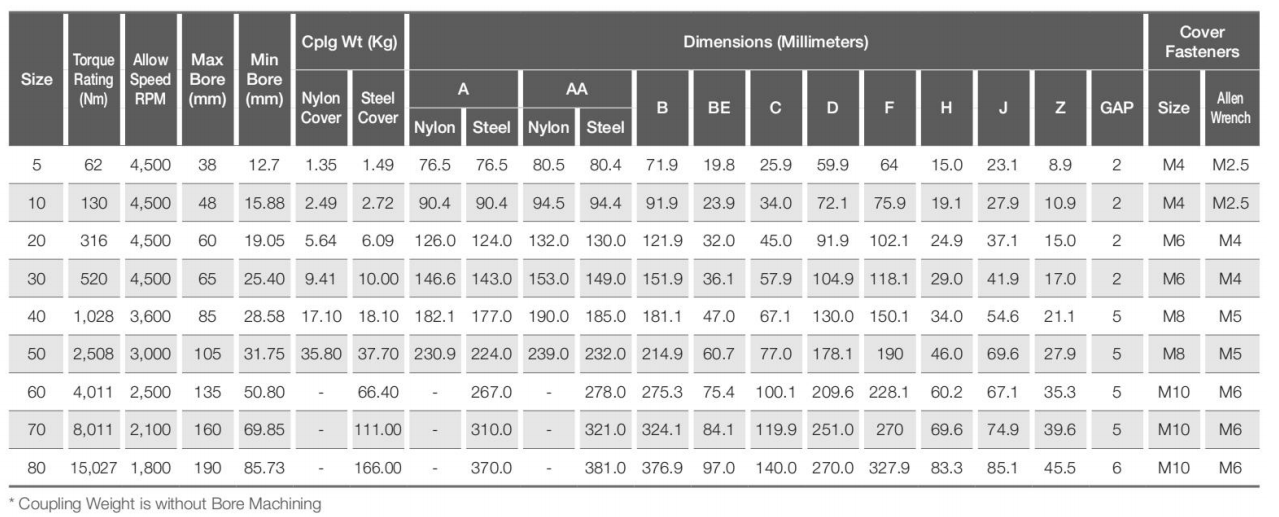

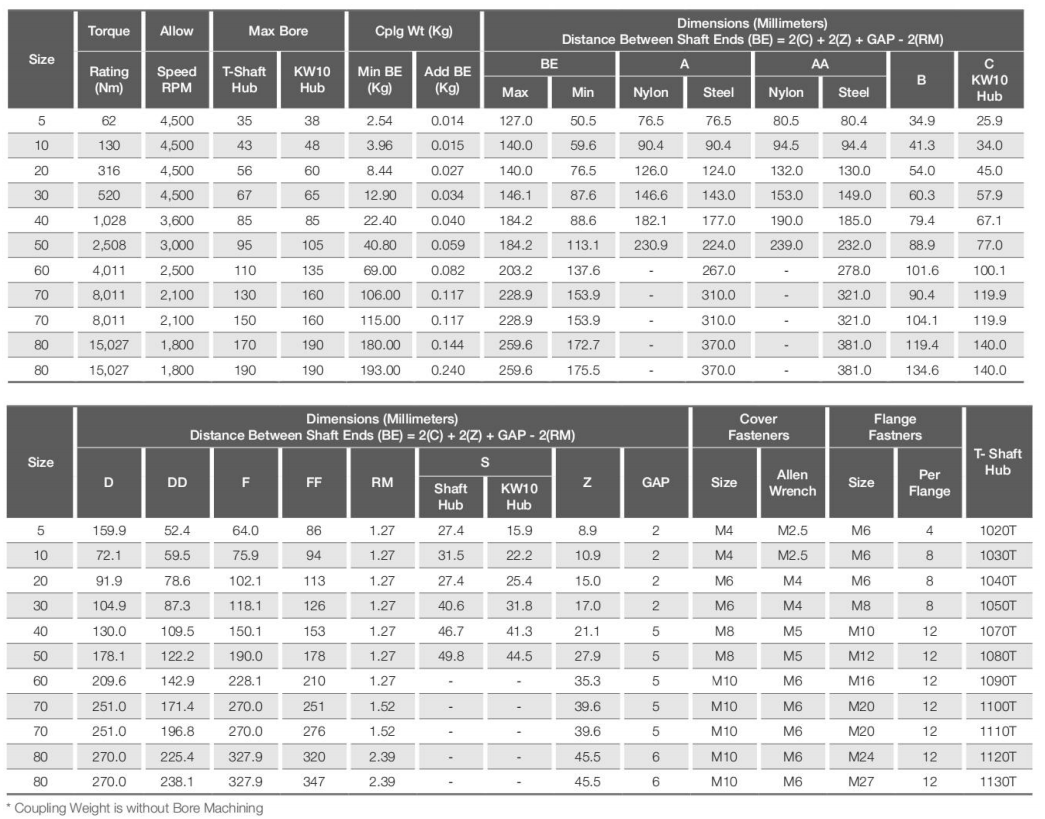

Advanced production methods and innovative material selection allows for a higher capacity at a more competitive price. Flex Coupling is non-lubricated and are designed from flexible urethane. The lack of need for lubrication decreases recurrent maintenance costs. Available in both close-coupled and spacer designs, Urethane Flexible Couplings accommodate shaft diameters up to 186mm and torque loads up to 15,028 Nm The urethane element has excellent resistance to wear and chemicals, and can be operated between temperatures of -40℃ to 95℃. The compact design of this coupling eliminates that need for coupling guard redesign for specific applications.

Features of Flexible Flex Coupling:

1.Flexible Flex Coupling High precision, high hardness, high quality, high stability

2.Flexible Flex Coupling has strong robustness, low noise and wear resistance

3.Flexible Flex Coupling is of higher quality and durable

Introduction of our factory

Global factories are located in Germany, South Korea, India, China and other places.Global factories are located in Germany, South Korea, India, China and other places. The company has passed BSI certification, and the manufacturing process is in line with ISO 9001 standards, applicable to GB, ISO, DIN standards, and API, ASME, AS standards when necessary. The key components are purchased from top global brands to ensure product quality.