High Speed Shaft Cross Kit Bearing Universal Joints

Universal joint is widely used in various heavy industrial machinery such as lifting, engineering transportation, mining, petroleum, shipping, coal, rubber, paper machinery, etc. due to its characteristics of deflection angle and high transmission torque, especially High Speed Shaft Cross Kit Bearing Universal Joints.

- Information

- Video

- Download

High Speed Shaft Cross Pin Universal Joints are mechanical transmission devices used to transfer torque and motion under high-speed rotation conditions. Compared to low-speed shaft cross pin universal joints, high-speed shaft cross pin universal joints are optimized in design and materials to meet the demands of high-speed operation.

Features

High-Speed Operation Capability:

High-speed shaft cross pin universal joints are precision-designed and dynamically balanced to operate stably under high-speed rotation conditions, reducing vibration and noise.

High-Precision Manufacturing:

Utilizing high-precision machining processes, they ensure accurate fit between components, minimizing friction and wear during high-speed operation.

Lightweight Design:

Made from high-strength, lightweight materials (such as alloy steel or composites), they reduce rotational inertia and improve response speed.

Excellent Dynamic Balance Performance:

Through dynamic balancing correction, they minimize unbalanced forces during high-speed operation, ensuring smooth performance.

Accommodates Angular Misalignment:

Capable of operating effectively with a certain degree of angular misalignment (typically 10°-15°), making them suitable for applications with imperfect shaft alignment.

High Torque Transmission Capacity:

Although primarily designed for high-speed applications, they can still transmit relatively high torque, making them suitable for high-speed, medium-to-high load scenarios.

Low Friction and Wear:

Equipped with high-performance bearings and lubrication designs, they reduce friction and wear, extending service life.

Modular Design:

Facilitates easy installation, disassembly, and maintenance, making them ideal for high-speed equipment requiring frequent servicing.

High Speed Shaft Cross Kit Bearing Universal Joints

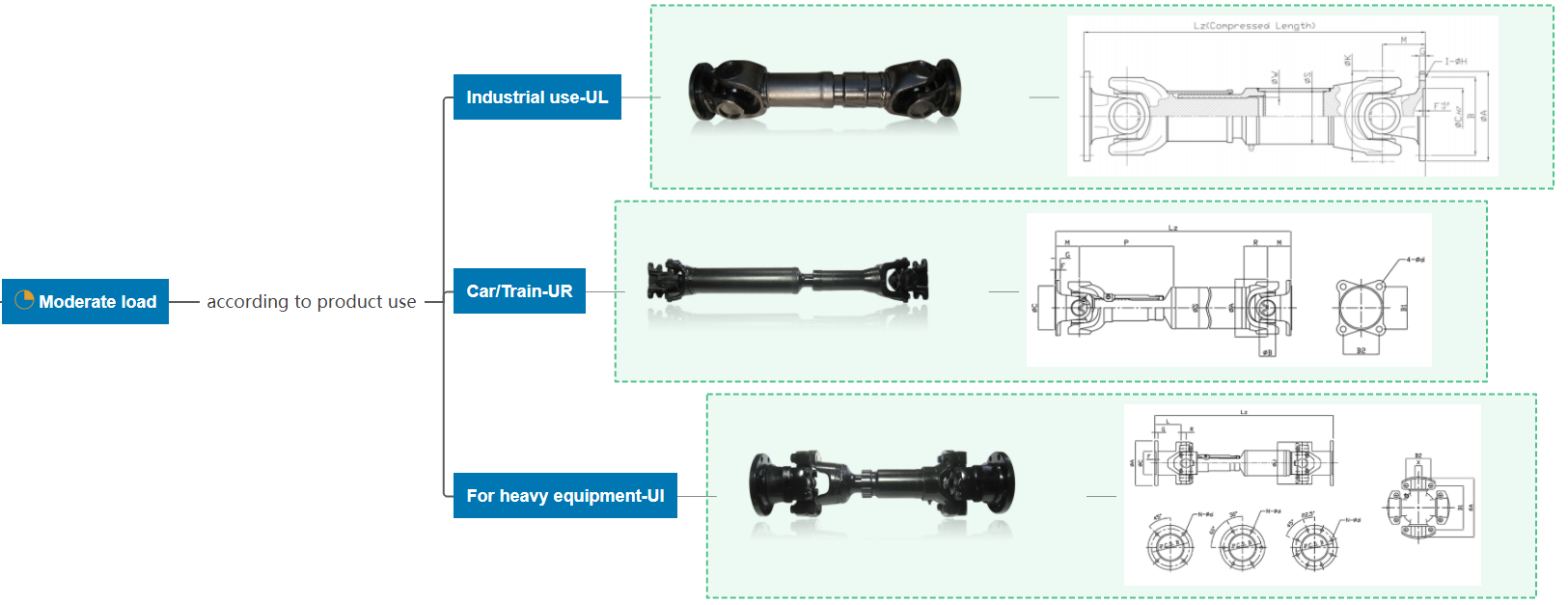

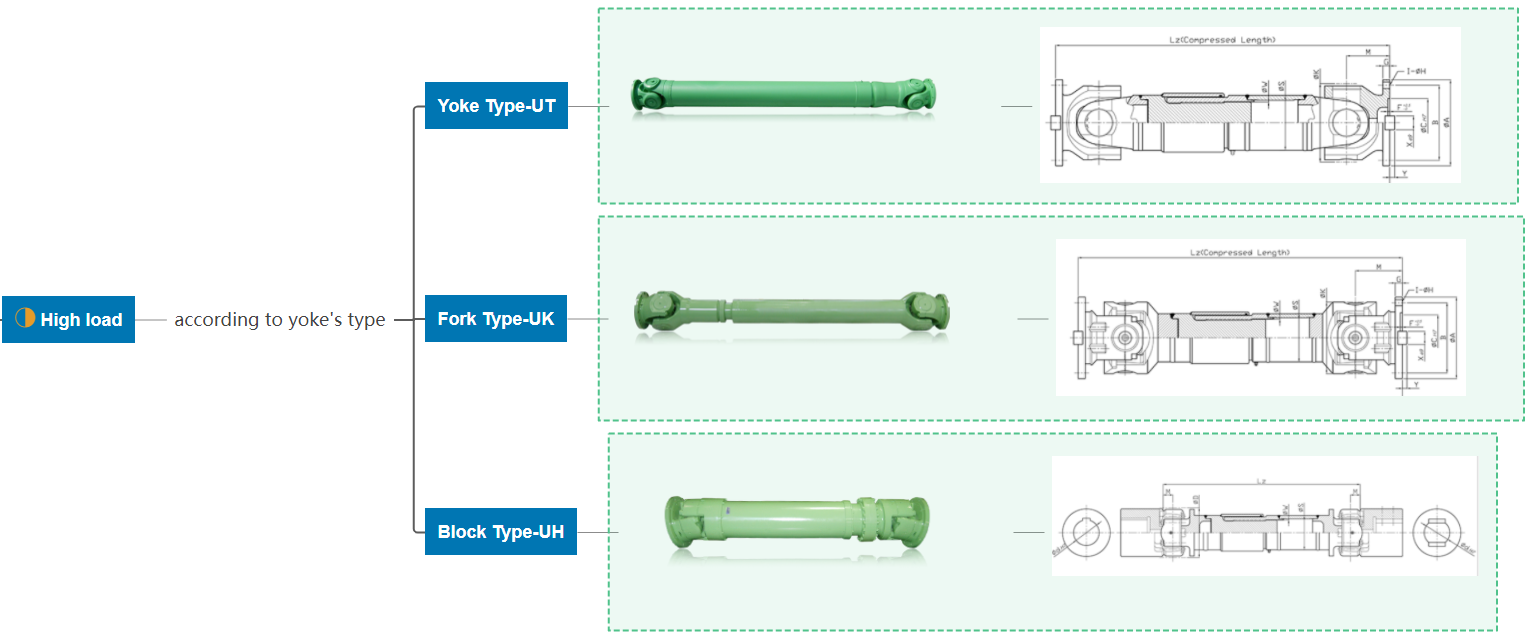

High speed universal joint can be divided into light, medium and heavy types according to load.

Please download our catalog for more information

World-class factory

Global factories are located in Germany, South Korea, India, China and other places.Global factories are located in Germany, South Korea, India, China and other places. The company has passed BSI certification, and the manufacturing process is in line with ISO 9001 standards, applicable to GB, ISO, DIN standards, and API, ASME, AS standards when necessary. The key components are purchased from top global brands to ensure product quality.