Low Speed Shaft Cross Pin Universal Joints

Low Speed Shaft Cross Pin Universal Joints

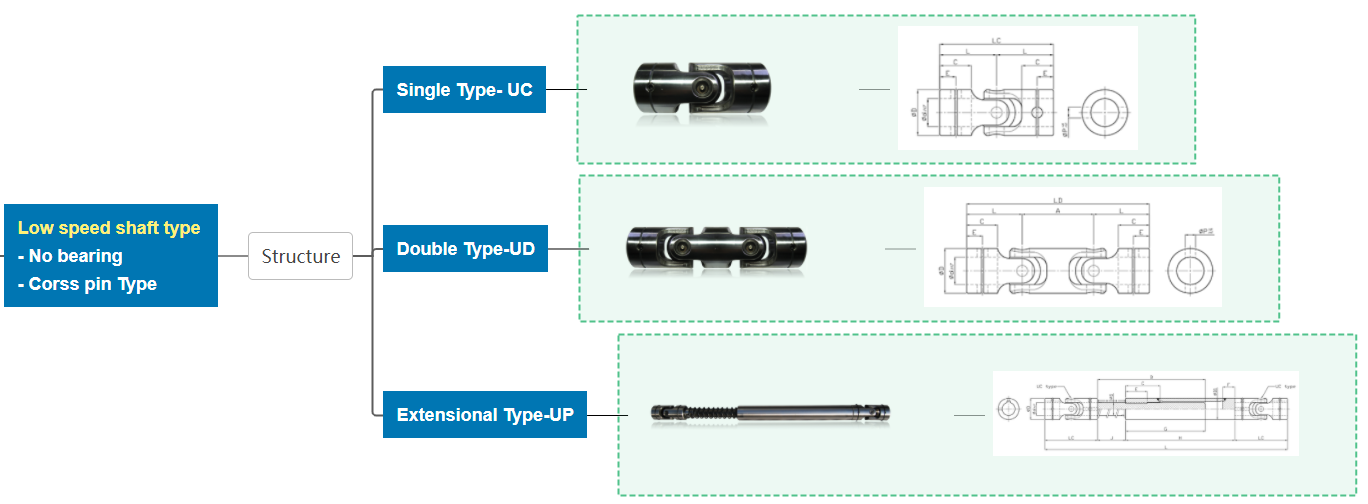

KUDOSWORLD Low Speed Shaft Universal Joints can be divided into single, double and extensional according to structrue.

- Information

- Video

- Download

Low Speed Shaft Cross Pin Universal Joints are a common mechanical transmission device primarily used to transmit torque and rotational motion between two non-collinear shafts. Their key feature is the ability to accommodate significant angular misalignment, making them perform exceptionally well in low-speed, high-torque applications.

Features

Accommodates Angular Misalignment:

Cross pin universal joints can operate effectively with a certain degree of angular misalignment (typically 15°-30°) between two shafts, making them suitable for applications where precise shaft alignment is difficult to achieve.

High Torque Transmission Capacity:

Thanks to their robust structural design, cross pin universal joints can transmit high levels of torque, making them ideal for low-speed, high-load applications.

Simple and Reliable Structure:

Composed of a cross pin, bearings, and yoke components, their simple structure makes them easy to manufacture and maintain.

They are highly durable and capable of long-term operation in harsh environments.

Low Cost:

Compared to other types of universal joints, cross pin universal joints have lower manufacturing costs, offering good economic value.

Allows Axial Displacement:

Certain designs permit a degree of axial displacement, further enhancing their adaptability and flexibility.

Suitable for Low-Speed Operation:

Due to their design characteristics, cross pin universal joints perform exceptionally well in low-speed operation. However, they may generate vibrations and noise during high-speed operation.

Low Speed Shaft Cross Pin Universal Joints

KUDOSWORLD Low Speed Shaft Universal Joints can be divided into single, double and extensional according to structrue.

Please download our catalog for more information

World-class factory

Global factories are located in Germany, South Korea, India, China and other places.Global factories are located in Germany, South Korea, India, China and other places. The company has passed BSI certification, and the manufacturing process is in line with ISO 9001 standards, applicable to GB, ISO, DIN standards, and API, ASME, AS standards when necessary. The key components are purchased from top global brands to ensure product quality.