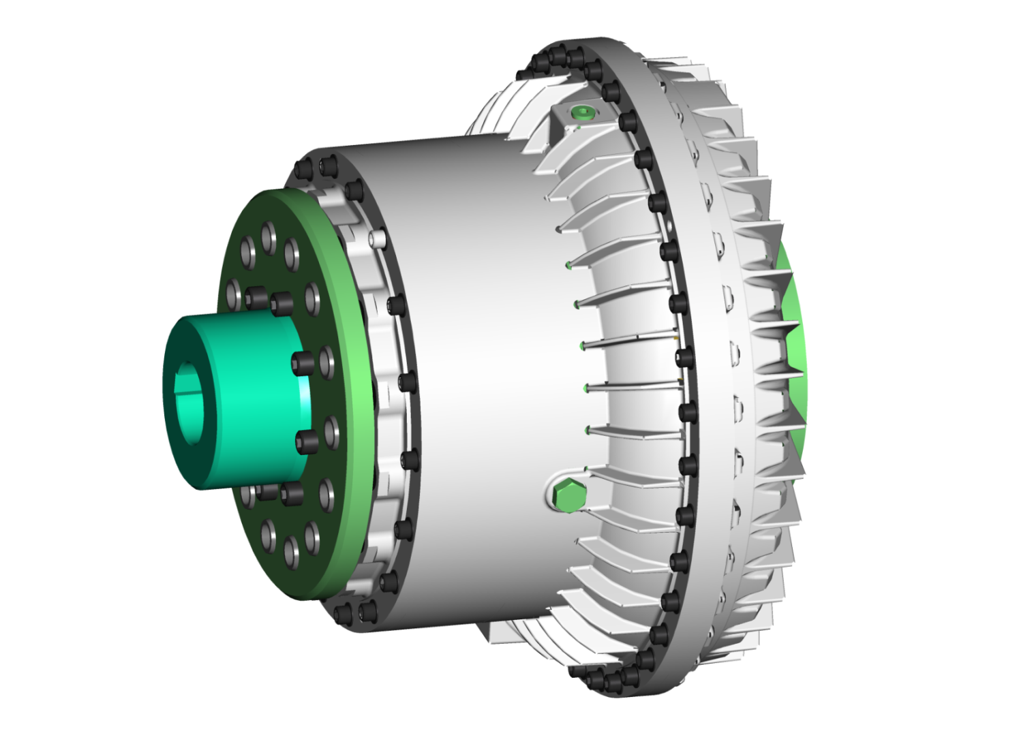

Hydrodynamic Coupling With Enlarged Delay Chamber

1. HR-CC type Hydrodynamic Coupling is equivalent to the basic Hydrodynamic Coupling with an enlarged delay chamber.

2. At start-up, there is less working oil in the working circuit, the working machine starts more smoothly, and the torque change during starting is more gentle. The Hydrodynamic Coupling protects the drive system from overload and reduces torsional vibration. Protecting the system and improving productivity.

3. HR-CC type Hydrodynamic Coupling is mainly used in the drive system of conveyor (belt conveyor, plate conveyor) and the drive system of crusher.

- KUDOSWORLD

- GERMANY

- 6-8 WORKING WEEKS

- 2,000 SETS/YEAR

- Information

- Video

- Download

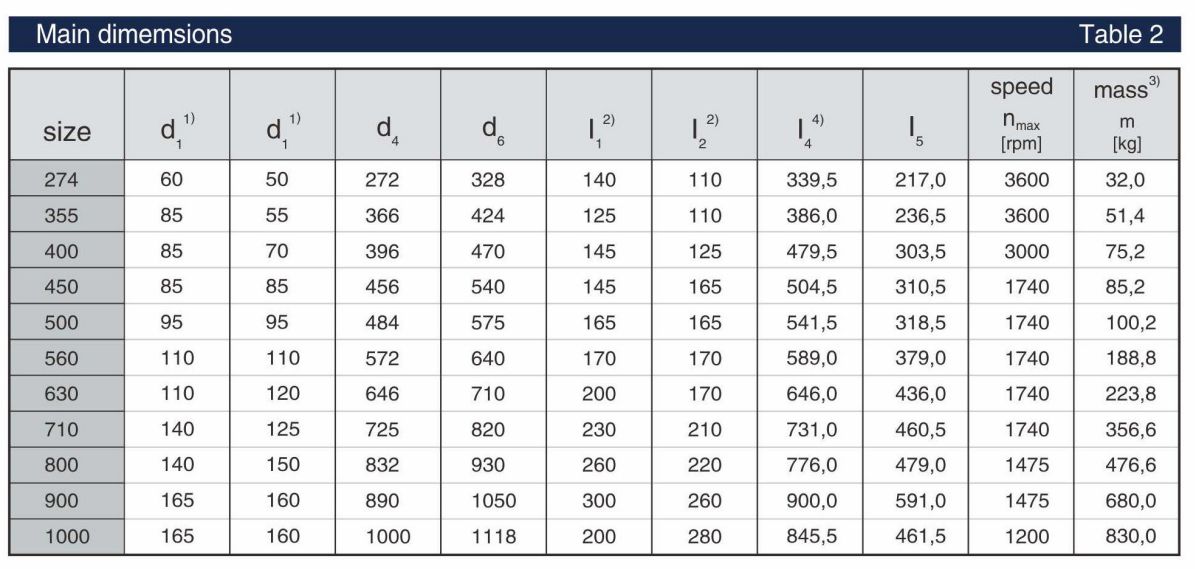

Specifications of Hydrodynamic Coupling With Enlarged Delay Chamber

Types of KUDOSWORLD Hydrodynamic coupling

Type HR

·Hydrodynamic coupling without delay chamber

Type HR-C

·Hydrodynamic coupling with delay chamber

Type HR-CC

·Hydrodynamic coupling with enlarged delay chamber

Type HR-D

· Hydrodynamic coupling with two hydrodynamic units

Type B

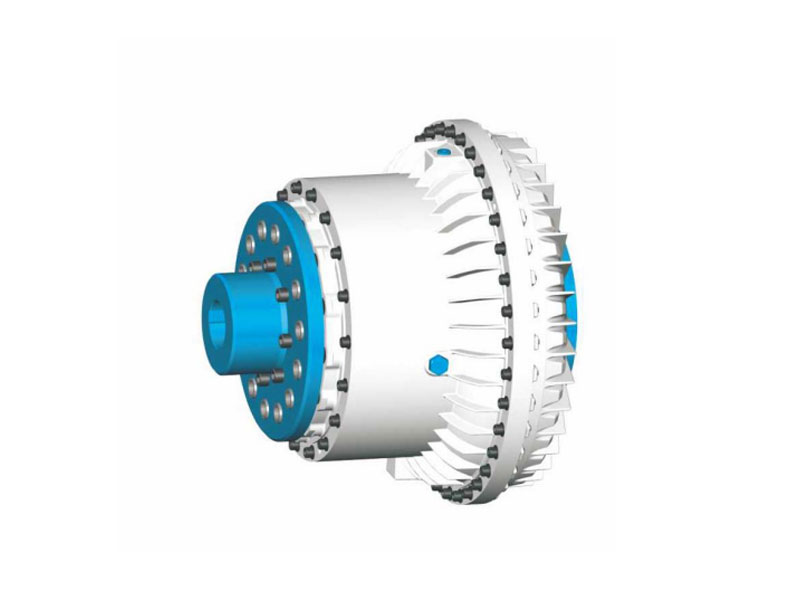

· Hydrodynamic coupling with brake drum

Ex):HR-B, HR-CB, HR-CCB, HR-DB

Type S

· Hydrodynamic coupling with brake disc

Ex):HR-S, HR-CS, HR-CCS, HR-DS

Type P

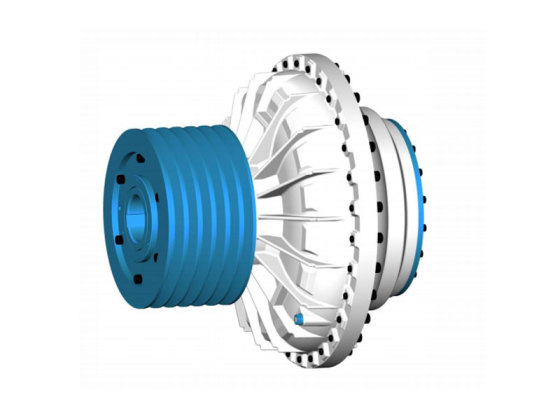

· Hydrodynamic coupling with pulley

Ex):HR-P, HR-CP, HR-CCP

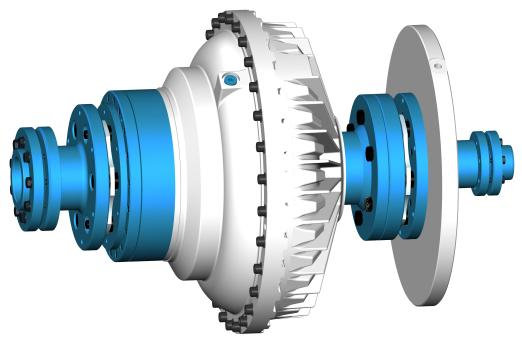

Type MRR

·Hydrodynamic coupling can be removed without moving both ends

·With flexible connecting coupling

Type MRW

·Hydrodynamic coupling can be removed without moving both ends

·Without flexible connecting coupling

Type MB

·The motor end bears the weight of the Hydrodynamic coupling

·With flexible connecting coupling

Optional Accessory

Water medium

The Hydrodynamic couplings can operate normally with water and glycol mixture as medium.

Water medium is more easy to purchase and meets high environmental requirements.

Hydrodynamic couplings with water medium need to add encapsulated devices such as oil seals or bearing sealing end caps to seal the bearings.

Rolling bearings do not need to be filled with oil, but only need grease to ensure service life.

When the water medium is used, the total length of the product will increase.

Balancing Test

Hydrodynamic couplings will be dynamically balanced. Standard balancing quality is Q6,3 at 1500rpm according to VDI 2060 in two planes.

If you need to choose other balanced quality standards, please contact us.

Insert shaft sleeve

The use of the inserted shaft sleeve can meet the requirements of different shaft diameters and shaft lengths. The inserted shaft sleeve can be processed and shipped according to the user's requirements.

Fusible plug

When the liquid temperature exceeds the melting point of the fusible plug, the fusible plug is ejected. In this way, the Hydrodynamic coupling is protected from overheating. Fusible plugs have a variety of temperature options.

Mechanical thermal switch device

The mechanical thermal switch is set with a lower temperature than the fusible plug to provide secondary protection for Hydrodynamic coupling. When the temperature of the temperature control plug of the mechanical switch is reached, a mechanical signal will be sent from the top of the temperature control plug. After the signal is obtained, the drive system will be cut off.

Electronic thermal switch device

Similar to the mechanical switch, it is a secondary protection for Hydrodynamic coupling from overheating. When the Limit temperature is reached, the sensor will send an electronic signal to the analysis unit and converted into another signal to cut off the drive system.

Protective cover

It is necessary to install a protective cover in order to avoid unintentional contact with the rotating elements of Hydrodynamic couplings. The manufacturing of the protective cover fully considers the cooling of the coupling through air circulation. We can provide standard protective cover or special designs according to customer requirements.

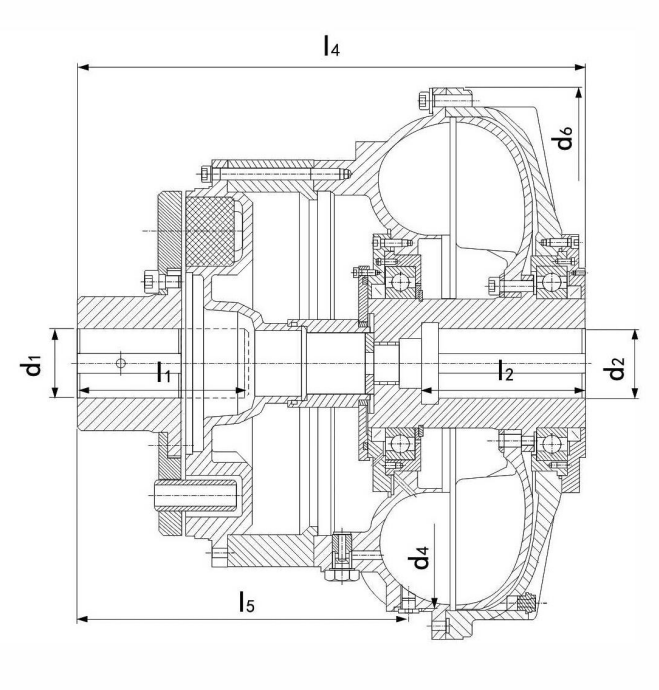

The structure of the hydraulic coupling

The hydraulic coupling is a kind of non-rigid coupling with liquid as the working medium. The pump wheel and turbine of the hydraulic coupler form a closed working chamber that can circulate the liquid. The pump wheel is mounted on the input shaft and the turbine is mounted on the output shaft. The two wheels are semi-circular rings with many blades arranged in the radial direction. They are coupled facing each other and do not touch each other. There is a gap of 3mm to 4mm in the middle, and form a ring-shaped working wheel. The driving wheel is called the pump wheel, the driven wheel is called the turbine, and both the pump wheel and the turbine are called the working wheel. After the pump impeller and the turbine are assembled, an annular cavity is formed, which is filled with working oil.

Kudosworld is an industrial technology group with businesses all over the world. We provide a series of solutions, including advanced technology, manufacturing, products and precision services. Provide products and services for key markets such as new energy, oil and gas, mines, ports, steel, etc. We take Kudosworld (China) as the core of operation and management, rely on the technology of Kudosworld in Germany, and cooperate with global production bases for processing and manufacturing.