Double Engagement Rigid Sleeve Gear Coupling

Gear coupling is a kind of positive locking and torsional rigid coupling used for torque transmission.

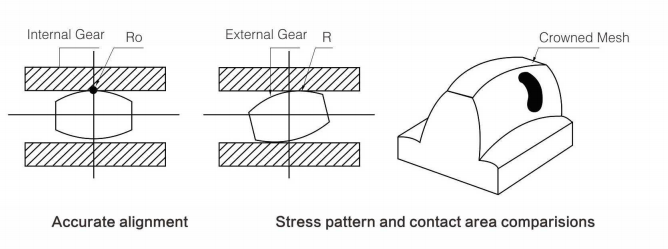

KUDOSWORLD Gear Couplings’triple-crowned teeth are crowned on the root, tip and face to articulate freely and minimize wear caused by misalignment.

By eliminating tip-loading while reducing backlash and radial clearances. KUDOSWORLD Gear Couplings’ triple-crowned teeth can help protect equipment from damaging loads.

- KUDOSWORLD

- GERMANY

- 6-8 WORKING WEEKS

- 2,000 SETS/YEAR

- Information

- Video

- Download

Introduction to Double Engagement Rigid Sleeve Gear Coupling:

Gear coupling is a kind of positive locking and torsional rigid coupling used for torque transmission. The hub is connected to the working machine by assembly key, gear shaft or interference fit assembly. The tooth shape of hub is realized by crown drum tooth. The tooth thickness decreases with the increase of tooth width. The engagement of the crown drum teeth makes the rotation range achieve a small backlash. The combination of small backlash and ring gear center allows the coupling to operate smoothly over the entire speed and torque range.

The KUDOSWORLD Double Engagement Rigid Sleeve Gear Coupling is a double engagement, close-coupled solution with two flex halves to accommodate offset, angular as well as axial misalignment. Engineered for all horizontal, close-coupled applications including but, not limited to, fans, overhead cranes, conveyors, steel and paper mill equipment. Adaptable to limit shaft end float for use with electric motors, generators and other machinery fitted with sleeve bearings.

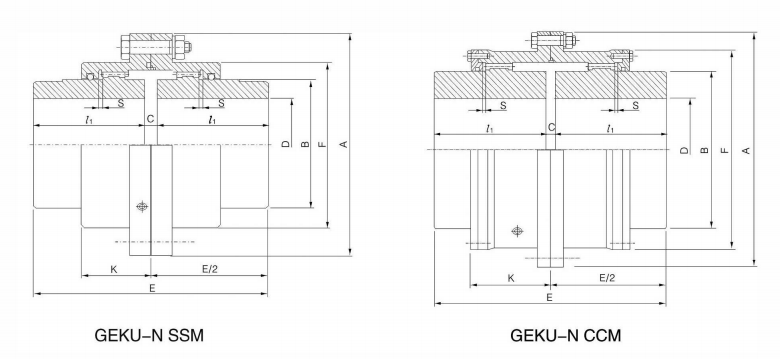

KUDOSWORLD Double Engagement Rigid Sleeve Gear Coupling is available in 2 TYPES:

Series SSM/CCM sizes ranging from SSM112 through SSM400, and CCM450 to CCM1250.

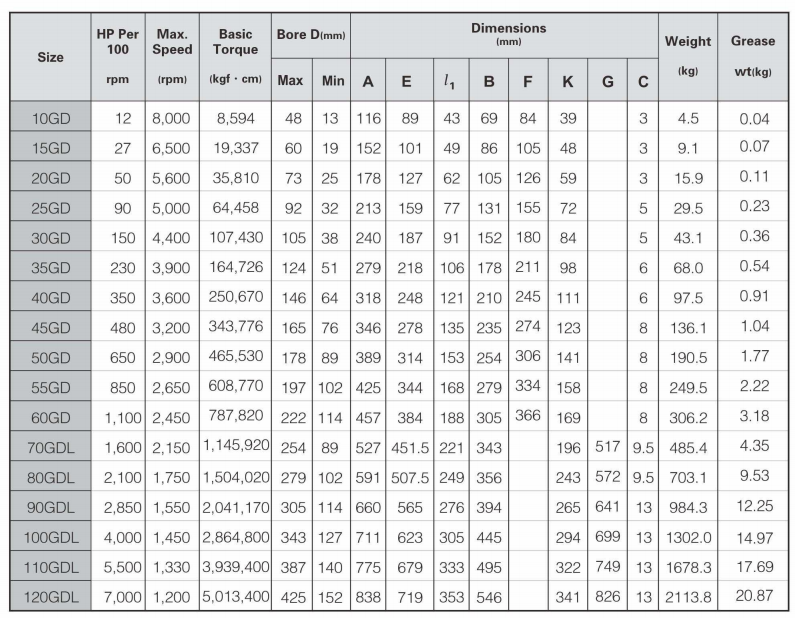

Series GD/GDL sizes ranging from 10GD through 60GD, and from 70GDL to 120GDL.

World-class factory

Global factories are located in Germany, South Korea, India, China and other places.Global factories are located in Germany, South Korea, India, China and other places. The company has passed BSI certification, and the manufacturing process is in line with ISO 9001 standards, applicable to GB, ISO, DIN standards, and API, ASME, AS standards when necessary. The key components are purchased from top global brands to ensure product quality.