Single Engagement Rigid Sleeve Gear Coupling

KUDOSWORLD Single Engagement Rigid Sleeve Gear Coupling is a single engagement design used with floating shafts or three bearing drive trains. Featuring one flex half and one rigid half, it is suited for accommodating angular misalignment.

- KUDOSWORLD

- GERMANY

- 6-8 WORKING WEEKS

- 2,000 SETS/YEAR

- Information

- Video

- Download

KUDOSWORLD Single Engagement Rigid Sleeve Gear Coupling is a single engagement design used with floating shafts or three bearing drive trains. Featuring one flex half and one rigid half, it is suited for accommodating angular misalignment.

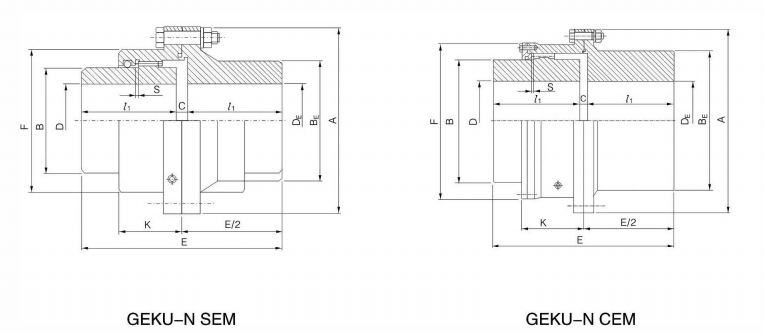

KUDOSWORLD Single Engagement Rigid Sleeve Gear Coupling is available in 2 TYPES:

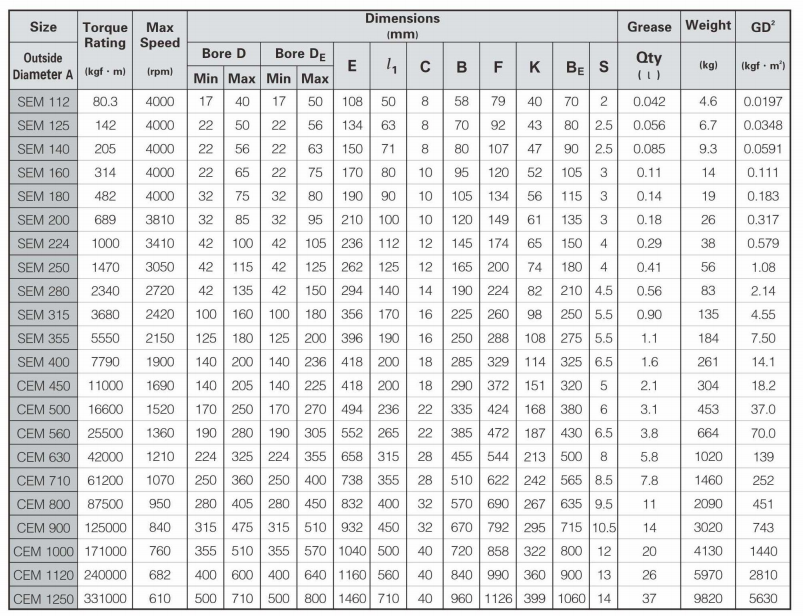

Series SEM/CEM sizes ranging from SEM112 through SEM400, and CEM450 to CEM1250.

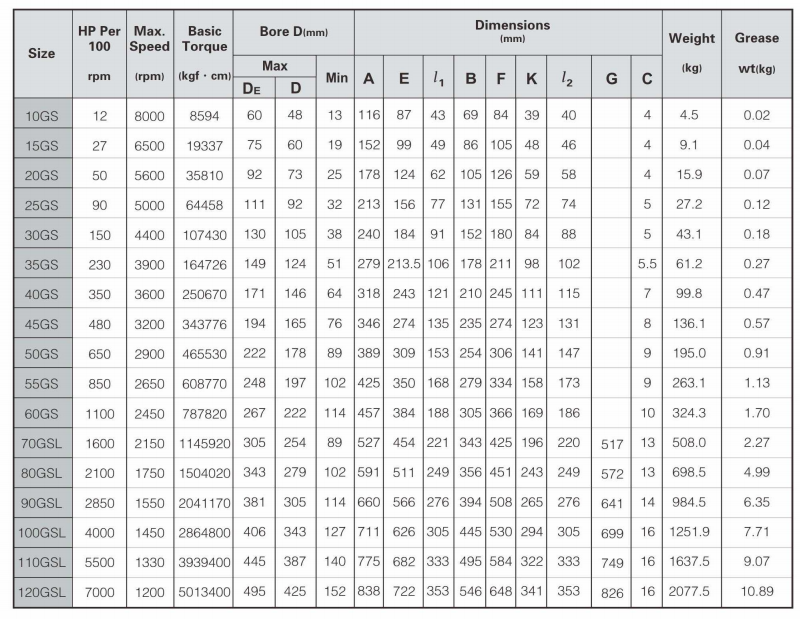

Series GS/GSL sizes ranging from 10GS through 60GS, and from 70GSL to 120GSL.

Application of Single Engagement Rigid Sleeve Gear Coupling:

Gear couplings have been standardized and serialized, and play a very good role in various machinery industries such as lifting, metallurgy, mining, lifting and transportation, oil and ships, such as winders, oil pump plants, cement mills, and swing conveyors.

Coupling removal precautions:

before the coupling is removed. Some marks can be made on the position where each part of the coupling fits with each other as a reference when reassembling. If there are many machines in a workshop and the maintenance of multiple pieces of equipment is carried out at the same time, the parts card should be hung for the disassembled parts, and the card should indicate which machine the part belongs to and which set of couplings . For small parts such as bolts, it is more necessary to take good care of them. For couplings used in high-speed machines, the connecting bolts have been weighed, and the marks must be removed. Make no mistake.

World-class factory

Global factories are located in Germany, South Korea, India, China and other places.Global factories are located in Germany, South Korea, India, China and other places. The company has passed BSI certification, and the manufacturing process is in line with ISO 9001 standards, applicable to GB, ISO, DIN standards, and API, ASME, AS standards when necessary. The key components are purchased from top global brands to ensure product quality.