More Designs OF Rigid Sleeve Gear Coupling

1. KUDOSWORLD have designed various types of gear couplings for different industries and different working conditions. 2.KUDOSWORLD More Designs OF Rigid Sleeve Gear Coupling make it easier to deal with even worse working conditions.

3. No matter what kind of heavy equipment is used, we can provide you with the most perfect design to ensure the smooth and efficient operation of the equipment.

4. Welcome to provide customized drawings and customized design of working condition parameters.

- KUDOSWORLD

- GERMANY

- 6-8 WORKING WEEKS

- 2,000 SETS/YEAR

- Information

- Video

- Download

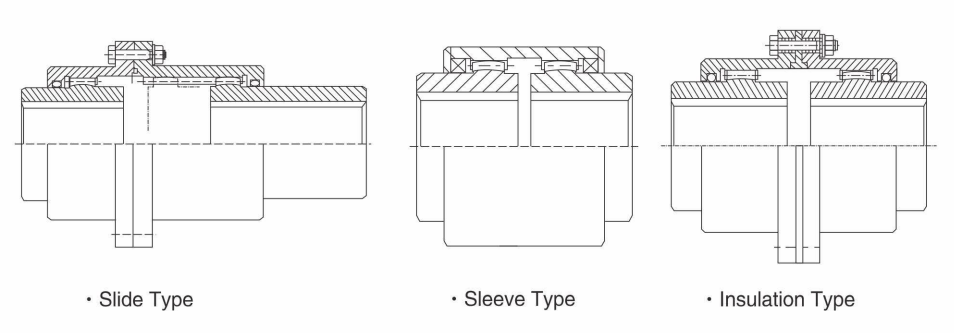

More Designs OF Rigid Sleeve Gear Coupling:

Slide Type

Sleeve Type

Insulation Type

Limited-end Play Type

Detachable Clutch Type

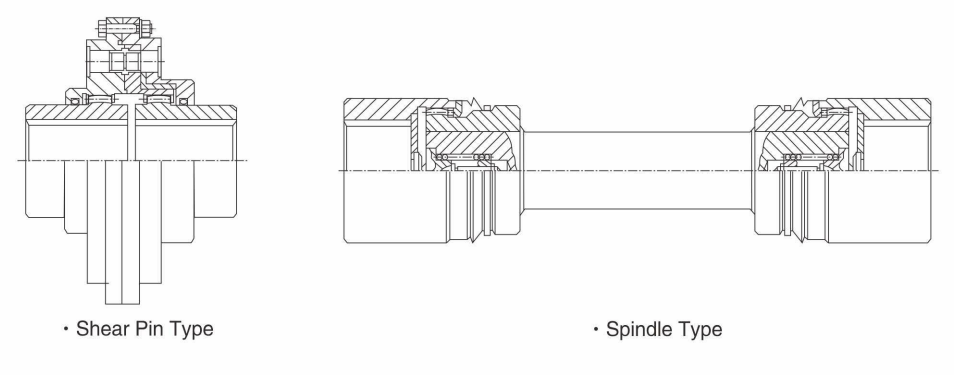

Shear Pin Type

Spindle Type

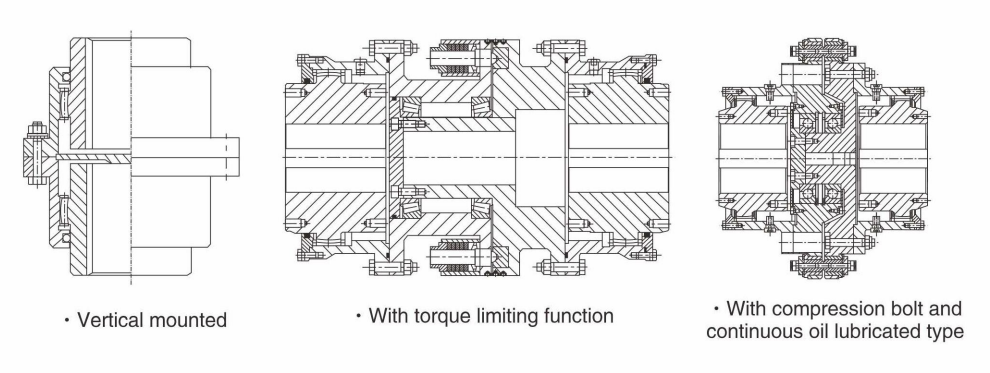

Vertical mounted

With torque limiting function

With compression bolt and continuous oil lubricated type

The gear coupling with brake disc is arranged on the wheel hub for transver drive of rolling mill

With the highest speed and oil lubricated

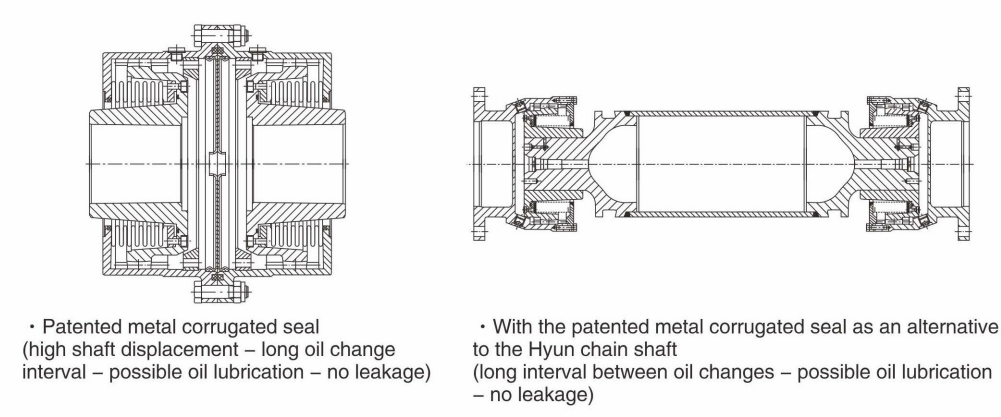

Patented metal corrugated seal (high shaft displacement-long oil change interval-possible oil lubrication-no leakage)

With the patented metal corrugated seal as an alternative to the Hyun chain shaft (long interval between oil changes -possible oil lubrication-no leakage)

Introduction of Gear Couplings

Gear coupling is a common mechanical part used by gear reducer to transmit torque. It consists of two parts, the driving shaft and the driven shaft. Most of the general power machines are connected to the working machine by means of it.

More Designs OF Rigid Sleeve Gear Coupling How it works:

The gear coupling is one of the movable rigid couplings. It uses the meshing of internal and external teeth to realize the transmission of torque and rotational motion between the two halves of the coupling. It is composed of main parts such as inner gear ring, gear shaft sleeve and end cover. Generally, small-sized gear coupling end cover and inner gear ring can form an integral type.

Technical support

Our technical services

KUDOSWORLD is dedicated to providing customers caring and comprehensive technical services. We not only pay attention to needs of customers, but also share values with customers, so that finally we could grow our business together. We believe our customers’ success equals our success.

In order to fulfill our commitment, we will:

1. Offer pre-sale and post-sale services.

We have a professional technical team that provides services such as product model selection, technical consultation, special working condition program design and on-site surveying and mapping.

2. After delivery, the after-sales team will provide technical services such as equipment installation, commissioning, daily maintenance guidelines.

3. We will pay regular visits to customers and maintain close communication with customers to gain feedback, as to address newly-arisen issues and provide timely remedy.

4. 24-hour service to ensure timely contact, and quick response.

Customers are our partners; we consider customers’ needs as our first priority. We endeavor to establish long-term and profound relationships with our clients, and become their trusted business partners.